July 24, 2018 (Santa Barbara, CA) Understanding and characterizing magnetic properties at the nanoscale is one of the key challenges in developing next-generation data storage and logic elements. The new Variable Field Module (VFM4) accessory for Asylum Research MFP-3D Atomic Force Microscopes (AFMs) enables measurements under applied in-plane and out-of-plane magnetic fields in order to better understand their effects on nanoscale magnetic domain structure. The VFM4 is capable of applying either an adjustable in-plane (±8000 G ) or out-of-plane (±1200 G) magnetic field to a sample and offers ~1 G field resolution. Researchers can learn more about the VFM4 and see recent results at http://afm.oxinst.com/VFM4.

“This new combination of capabilities has allowed one customer at a national synchrotron facility to use AFM for research that was previously only possible with very costly and time-consuming scanning x-ray transmission microscopy (SXTM),” said Dr. Maarten Rutgers, Director of New Product Introduction. “No other AFM commercial solution offers the same capabilities, versatility, and ease of use for magnetics research. While the VFM has traditionally been used for magnetic force microscopy experiments, it can also be used with techniques like conductive AFM (CAFM) and on a wide range of diverse samples including piezoelectric and ferroelectric materials.”

The VFM4 easily attaches to most Asylum Research MFP-3D AFMs and includes replaceable pole tips to quickly adapt between in-plane and out-of-plane configurations. It maintains a steady magnetic field with rare-earth magnets that produce no heat, thermal drift, or mechanical vibration. For experiments where both an applied magnetic field and a high tip-sample voltage bias are required, there is an optional high-voltage kit to adapt the VFM4 for safe application of voltages up to ±220 Volts.

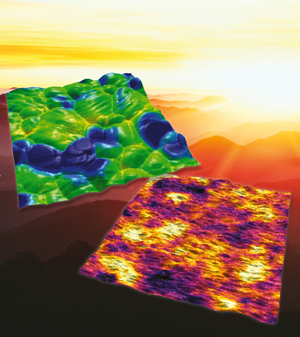

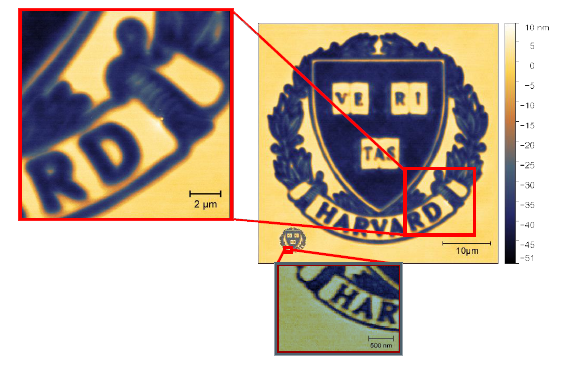

Image caption: Magnetic skyrmions in Co-based thin film pads imaged with MFM under out-of-plane magnetic fields. Image courtesy of K. Bouzehouane, Unité Mixte de Physique CNRS, Thales, Univ. Paris-Sud, Université Paris-Saclay France.

Download PDF

About Oxford Instruments Asylum Research

Oxford Instruments Asylum Research is the technology leader in atomic force microscopy for both materials and bioscience research. Asylum Research AFMs are widely used by both academic and industrial researchers for characterizing samples from diverse fields spanning material science, polymers, thin films, energy research, and biophysics. In addition to routine imaging of sample topography and roughness, Asylum Research AFMs also offer unmatched resolution and quantitative measurement capability for nanoelectrical, nanomechanical and electromechanical characterization. Recent advances have made these measurements far simpler and more automated for increased consistency and productivity. Its Cypher™ and MFP-3D™ AFM product lines span a wide range of performance and budgets. Asylum Research also offers its exclusive SurfRider™ AFM probes among a comprehensive selection of AFM probes, accessories, and consumables. Sales, applications and service offices are located in the United States, Germany, United Kingdom, Japan, France, India, China and Taiwan, with distributor offices in other global regions.

About Oxford Instruments plc

Oxford Instruments designs, supplies and supports high-technology tools and systems with a focus on research and industrial applications. Innovation has been the driving force behind Oxford Instruments’ growth and success for over 50 years, and its strategy is to effect the successful commercialisation of these ideas by bringing them to market in a timely and customer-focused fashion.

The first technology business to be spun out from Oxford University, Oxford Instruments objective is to be the leading provider of new generation tools and systems for the research and industrial sectors with a focus on nanotechnology. Its key market sectors include nano-fabrication and nano-materials. The company’s strategy is to expand the business into the life sciences arena, where nanotechnology and biotechnology intersect.

This involves the combination of core technologies in areas such as low temperature, high magnetic field and ultra high vacuum environments; Nuclear Magnetic Resonance; x-ray, electron, laser and optical based metrology; atomic force microscopy; optical imaging; advanced growth, deposition and etching.

Oxford Instruments aims to pursue responsible development and deeper understanding of our world through science and technology. Its products, expertise, and ideas address global issues such as energy, environment, security and health.

For further information please Contact Us

We are looking forward to seeing you at our workshop!

We are looking forward to seeing you at our workshop!

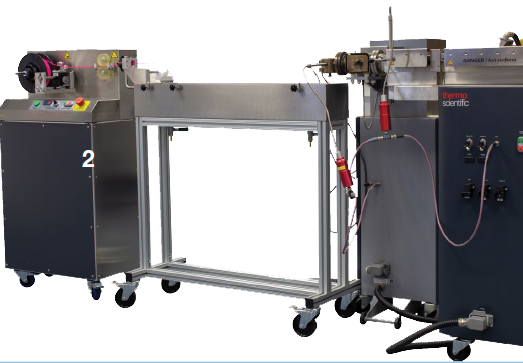

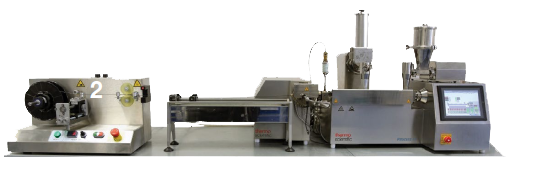

Streamline 3D filament development by combining compounding and filament formation in one system. Based on our twin-screw extruders, we have designed two systems that allow you to quickly test different formulations and produce spooled 3D filaments in fewer steps than traditional workflows. Both systems produce filaments directly from the compounding process by using a melt pump for pulsation-free output, which ensures a precise filament diameter and significantly reduces time and labor costs. The thermal stress on the filament material is also reduced by eliminating unnecessary heat-cool cycles that occur if mixing and filament production are separated.

Streamline 3D filament development by combining compounding and filament formation in one system. Based on our twin-screw extruders, we have designed two systems that allow you to quickly test different formulations and produce spooled 3D filaments in fewer steps than traditional workflows. Both systems produce filaments directly from the compounding process by using a melt pump for pulsation-free output, which ensures a precise filament diameter and significantly reduces time and labor costs. The thermal stress on the filament material is also reduced by eliminating unnecessary heat-cool cycles that occur if mixing and filament production are separated.