What is XPS?

X-ray photoelectron spectroscopy (XPS) is a powerful surface analysis technique used to identify the elements in and the chemical states of the top layers of materials. It works by bombarding the surface of a material with X-rays (photons) and then measuring the kinetic energy of the photoelectrons ejected from the surface of a material. This energy is directly related to the photoelectrons’ binding energy within the parent atom and is characteristic of the element and its chemical state. Only electrons generated near the surface can escape without losing too much energy for detection. As a result, XPS data is obtained only from the top few nanometers of the surface. XPS surface selectivity, combined with quantitative chemical state identification, makes XPS highly useful in many applications, including battery research.

Vital role of battery research

Batteries have a vital role to play in the world’s transition from fossil fuels to renewable energy. In 2022, EVs accounted for 10% of global vehicle sales and by 2030 they are expected to reach 30% of global vehicle sales. Governments around the world are contributing to this growth through policies that are directing billions of dollars into battery research and manufacturing and by providing subsidies for consumers to purchase EVs. Ambitious cost and performance targets for the electrification of transportation will require the development of next-generation batteries produced on a commercial that are cost-effective, safe, renewably sourced, and high-performing with long lifetimes.

How XPS is used in battery research

There are multiple components and interfaces that are crucial to understand to develop high-performing and stable batteries. These include the cathode, anode, separator, electrolyte, and all interfaces formed between these layers, particularly the electrode-electrolyte interfaces. XPS can be used to study all of these materials and interfaces, such as next-generation cathode/anode active materials and how their composition changes with cycling; how the solid electrolyte interphase (SEI) layer varies in composition as a function of depth; and how surface pre-treatments affect the chemistry of the active electrode material. The quantitative chemical-state information provided by XPS makes it a versatile tool to understand many properties and guide the design of optimized batteries that meet ambitious targets.

Battery research challenges and XPS solutions:

- Analyzing SEI layer growth: Ongoing charging and discharging of a battery causes the SEI layer to form on the anode, reducing battery capacity. Analysis of the SEI layer helps researchers better understand and control this phenomenon and thereby improve battery performance and longevity. XPS depth profiling can chemically characterize the complex mixture that makes up the SEI layer, from the anode side all the way to the electrolyte side, for chemical understanding of the entire layer.

- Investigating the role of impurities and contaminants: Impurities and contaminants in battery materials can adversely affect performance and safety. XPS is highly sensitive to trace elements and can identify the presence and identity ofimpurities or contaminants on the surfaces of battery materials, helping researchers understand the sources of impurities and their impact on battery performance.

- Understanding the stoichiometry of solid electrolyte films: Chemical state analysis provided by XPS can be used to identify the stoichiometry of materials, including depth profiling to quantify elements at each depth and track any differences in stoichiometry throughout a film.

- Studying interface chemistry: Interfaces between different components of a battery play a crucial role in battery performance and long-term stability. XPS provides insights into the chemistry of interfaces, helping researchers optimize interface design for enhanced performance.

- Examining degradation in separator chemistry: XPS can provide valuable insights into degradation in separator chemistry during a cell’s lifetime by analyzing the surface chemistry and composition of the separator material.

- Environmental impact and recycling: XPS can be used to analyze the chemical composition of battery materials before and after recycling processes. It can help assess the effectiveness of recycling methods and the feasibility of reusing materials.

- Analyzing in situ electrode cycling: In situ XPS experiments can provide real-time insights into the electrochemical behavior and surface chemistry of electrode materials during cycling.

The best XPS for battery research from SRC

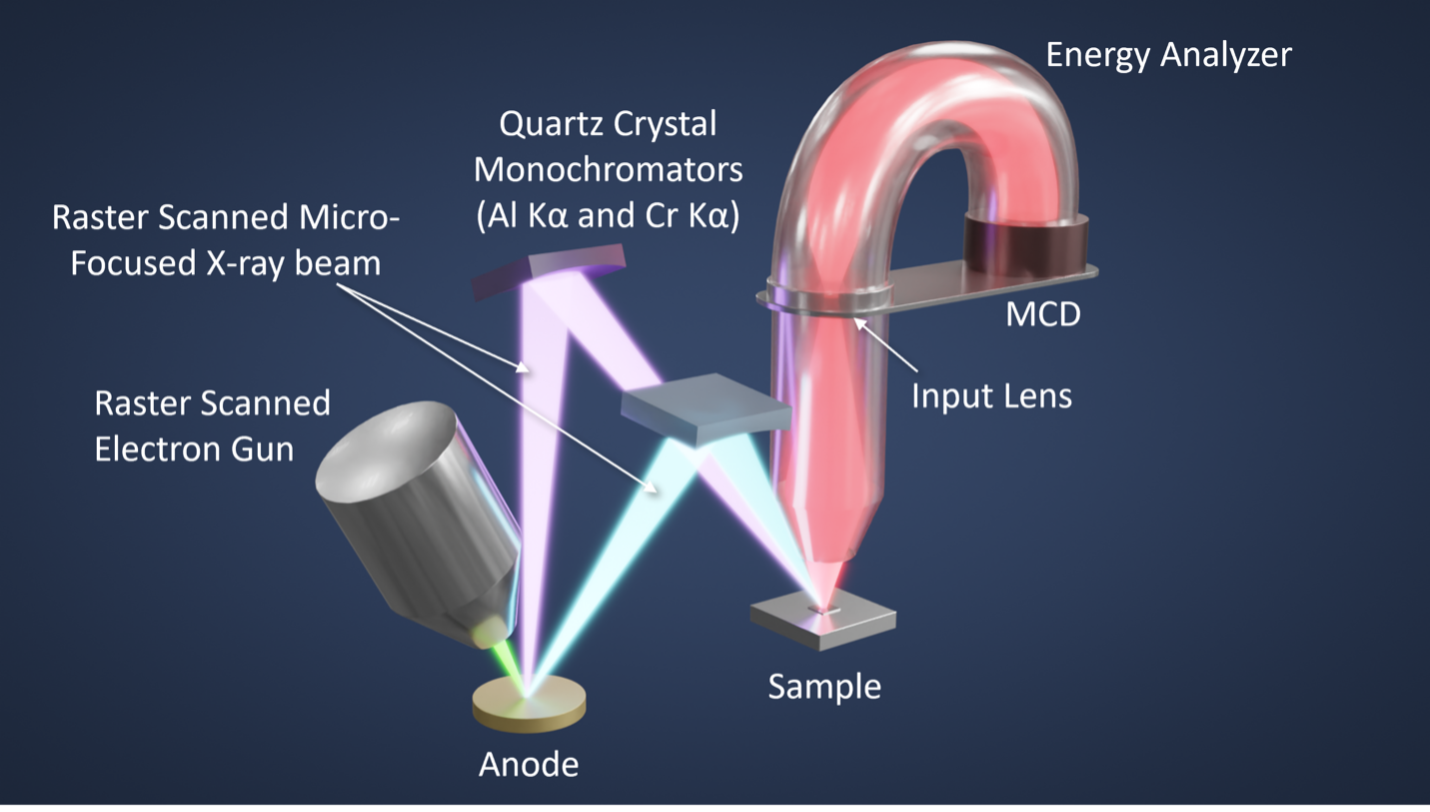

PHI’s XPS instruments use a unique scanned, finely-focused X-ray beam to create X-ray induced secondary electron images (SXIs), similar to an SEM, for easy sample navigation with 100% certainty in analysis position. This imaging capability can be used to easily drive around the sample in live mode or to save positions for compositional analysis including point or large-area spectroscopy, line scans, depth profiling, or chemical mapping. The size of the X-ray beam can be selected to support the efficient analysis of larger samples with homogeneous composition or small heterogeneities. This feature is indispensable for analyzing battery materials and interfaces, ensuring identification of impurities or other heterogeneities in composition, and absolute certainty that data is acquired from the exact feature of interest. In contrast to SEM/EDS, which has a typical analysis depth of 1-3 µm, XPS is a surface-sensitive technique with a typical analysis depth of less than 5 nm, making it better suited for the compositional analysis of ultra-thin layers and thin microscale sample features.

The PHI Genesis is the latest generation of PHI’s highly successful multi-technique XPS product line with PHI’s patented, monochromatic, micro-focused, scanning X-ray source. It is an easy-to-use, fully automated system with auto-tuning and calibration and multiple parking positions for high throughput. The fully integrated multi-technique platform of the PHI Genesis offers an array of optional excitation sources, sputter ion sources, and sample treatment and transfer capabilities that are all aligned to the same sample location. These features are essential in studying all relevant properties of advanced battery materials and interfaces, including small impurities or compositional heterogeneities, access to buried interfaces, electronic energy gap measurements, and operando experiments for a direct link between chemistry and performance. PHI Genesis offers high sensitivity and high throughput for large areas and small areas down to 5 µm and unique high-throughput non-destructive depth profiling using the optional hard X-ray Cr source. The instrument is fully customizable to address all analytical needs.

For more information on how PHI Genesis can be used to address your battery characterization challenges, please visit the PHI YouTube channel to watch a recent PHI.

Contact Us:

Click here to contact SRC and speak directly with experts on PHI’s Genesis.