Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

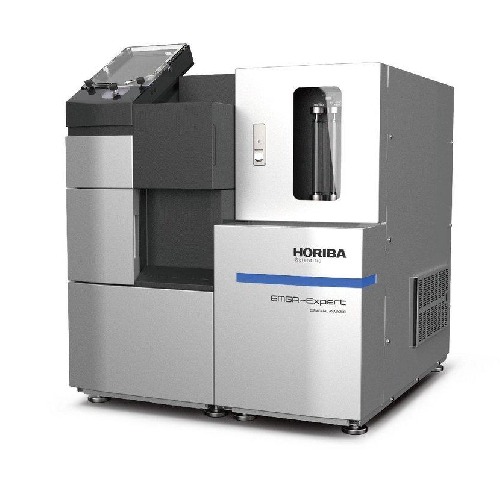

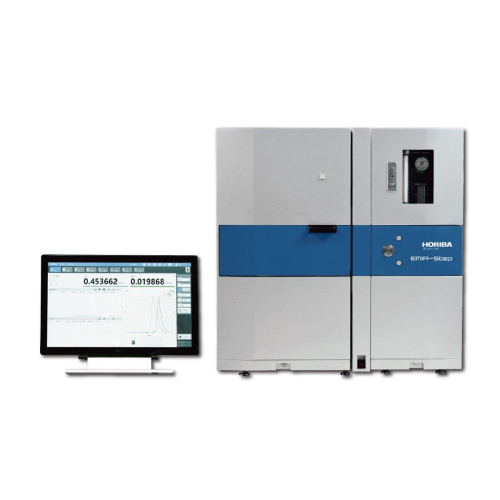

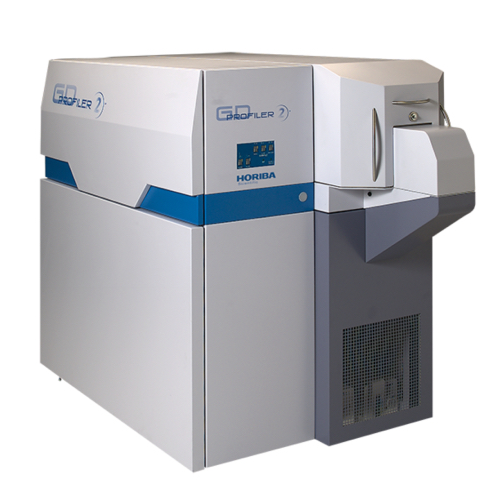

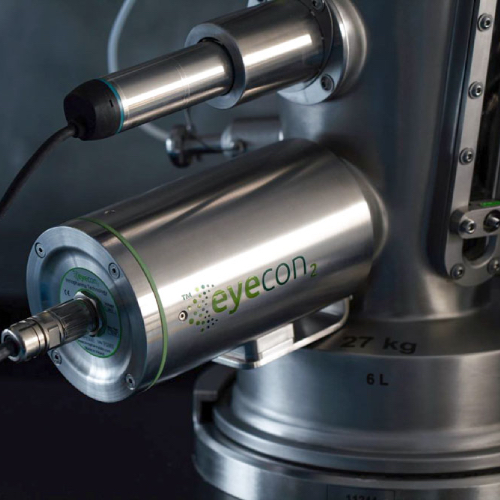

Materials Characterization

Materials characterization instruments analyze the physical and chemical composition of materials. Examples are thermal analysis instruments that determine heat flow capacity of carbon storage material, Raman Microscopes that determine the chemical signature of surfaces, and optical instruments that measure the stability and particle size distribution of emulsions.