Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

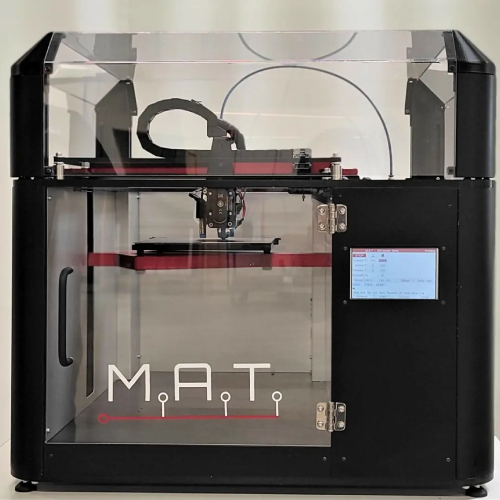

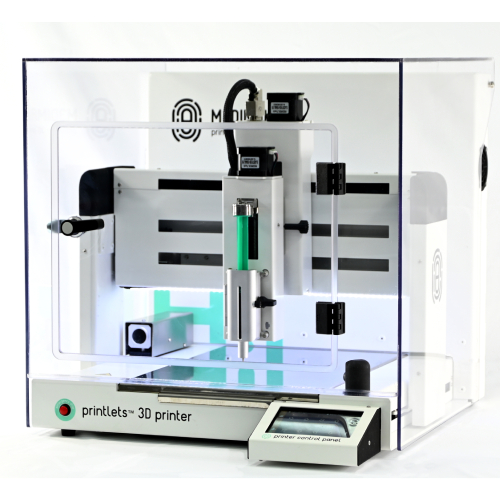

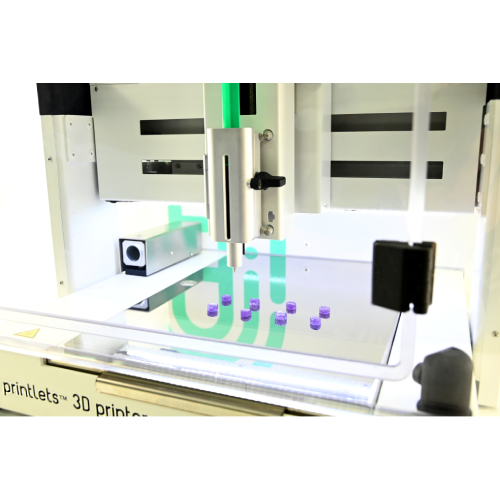

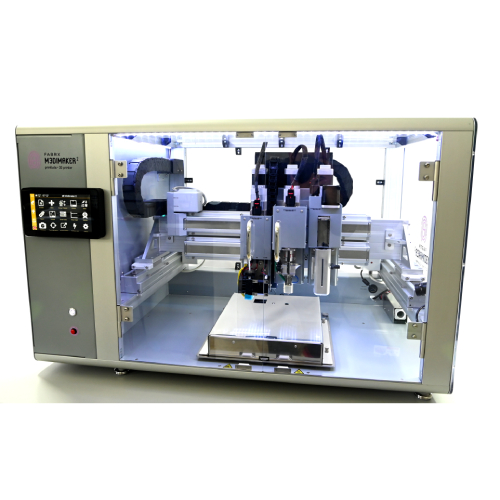

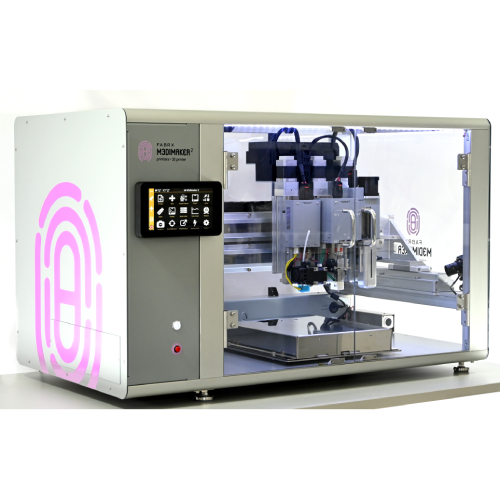

3D Printing

| 3D printing or Additive Manufacturing covers a variety of processes under computer control in which material is joined or solidified most often layer by layer to create a three-dimensional object or structure based on a digital 3D model or a computer-aided design (CAD) file.One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries.

While earlier considered almost exclusively for product development and rapid prototyping applications, nowadays Additive Manufacturing is widely used in the following sectors: manufacturing (circuit boards, ,…), life science/medical (medical devices, prosthetics, reconstructive surgery, organ transplant, 3D cell culture and drug screening, personalized medicine with customized pill dosage,…), industry (cosmetics, food, transportation, aerospace, military…) and sociocultural/arts (fashion, clothing, footwear, jewelry, toys,…). SRC, in its quest to provide leading edge technologies to potentiate the R&D capabilities of the Canadian scientific community, has recently integrated in its portfolio 3D printing technologies from several world-leading manufacturers such as Cellink for their 3D-bioprinters and bioinks and Apium Additive Technologies GmbH for their industrial and medical 3D printers of High Performance Polymers and Metals. Below is a list of partners we work with in this field: |