OVERVIEW

OVERVIEW

The MicroDamp Series vibration isolators are an affordable and effective solution, optimized to any instrument’s weight and dimension profile. Utilizing a polished aluminum housing and highly damped composite material, the MicroDamp Series provides a cost-effective solution for instruments experiencing broad frequency vibration noise within their lab environment.

PRODUCT HIGHLIGHTS

- Affordable and efficient vibration isolation

- Minimal amplitude within resonant frequency

- Compact, modular form factor

- Wide range of supported instrument weights

- Easy to integrate into existing instrument setups

- No air or electricity required

- Light-weight and easy to install/use

|

|

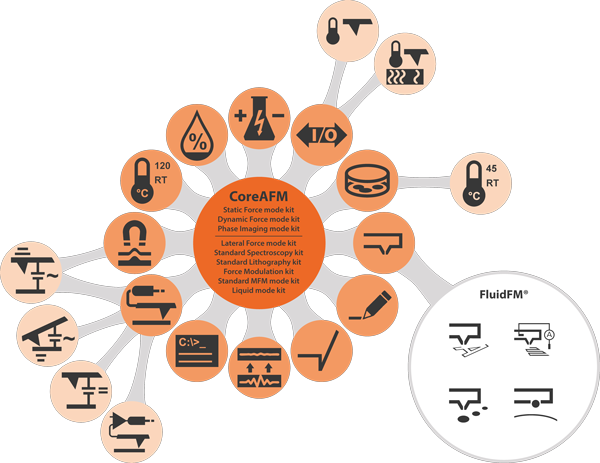

APPLICATIONS

- Optical Microscopy

- Interferometry

- Profilometry

- Microbalanace Systems

- Precision Inspection Stations

- Highly Sensitive Lab Equipment

- And More!

|

SELECTION GUIDE

The MicroDamp series often utilizes three to four isolators within a vibration isolation platform, depending on the supported instrument’s dimension profile and overall weight distribution. When paired with a damped top plate (i.e. granite, aluminum, breadboard, etc.), the MicroDamp Series becomes a complete solution for instruments requiring a stable and reliable vibration isolation platform.

The MicroDamp series often utilizes three to four isolators within a vibration isolation platform, depending on the supported instrument’s dimension profile and overall weight distribution. When paired with a damped top plate (i.e. granite, aluminum, breadboard, etc.), the MicroDamp Series becomes a complete solution for instruments requiring a stable and reliable vibration isolation platform.

To determine the correct isolator configuration for your instrument, review the MicroDamp models below and locate the model able to sufficiently support the weight of your instrument.

Please note: the values listed below are for individual isolators only. To correctly select the relevant model for your instrument, multiply the minimum/maximum load capacities by three to determine the total minimum/maximum load capacities. Your instrument must fall within this range to receive optimal vibration isolation performance. If your instrument’s weight does not fall within this range, multiply the minimum/maximum load capacities by a larger number (>3) until your instrument falls within range.

HELPFUL TIP

For further instruction on the correct configuration for your instrument, contact a Herzan representative and share your instrument’s weight, dimensions, and approximate load distribution. Once that information has been received, a tailored recommendation will be made to ensure your instrument receives maximum vibration isolation performance from a MicroDamp Series platform.

The Thermo Scientific™ HAAKE™ MARS rheometer, designed for reproducibility, coupled with easy workflow for careful preparation of your sample, is all the difference you need.

The Thermo Scientific™ HAAKE™ MARS rheometer, designed for reproducibility, coupled with easy workflow for careful preparation of your sample, is all the difference you need.