Optimize formulation and production in fewer steps

Advantages of twin-screw extrusion for fused filament fabrication (FFF)The Thermo Scientific™ Process 11 Twin-screw Extruder and the Thermo Scientific™ HAAKE™ PolyLab OS Rheomex PTW Twin-screw Extruder offer significant benefits over single-screw extruders for 3D filament development to help:

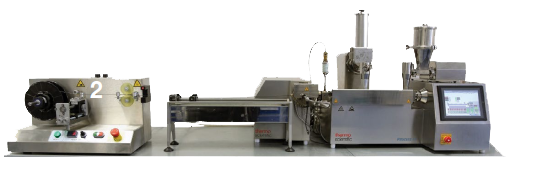

Thermo Scientific™ Process 11 Lab-scale 3D Filament Production System

|

| FL53142-3D Filament Systems Promo-EN-FL-53142-FINAL |

Reduce 3D filament development time

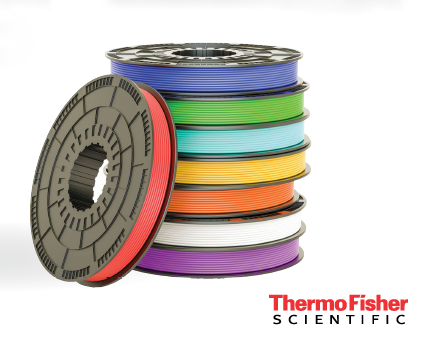

Streamline 3D filament development by combining compounding and filament formation in one system. Based on our twin-screw extruders, we have designed two systems that allow you to quickly test different formulations and produce spooled 3D filaments in fewer steps than traditional workflows. Both systems produce filaments directly from the compounding process by using a melt pump for pulsation-free output, which ensures a precise filament diameter and significantly reduces time and labor costs. The thermal stress on the filament material is also reduced by eliminating unnecessary heat-cool cycles that occur if mixing and filament production are separated.

Streamline 3D filament development by combining compounding and filament formation in one system. Based on our twin-screw extruders, we have designed two systems that allow you to quickly test different formulations and produce spooled 3D filaments in fewer steps than traditional workflows. Both systems produce filaments directly from the compounding process by using a melt pump for pulsation-free output, which ensures a precise filament diameter and significantly reduces time and labor costs. The thermal stress on the filament material is also reduced by eliminating unnecessary heat-cool cycles that occur if mixing and filament production are separated.

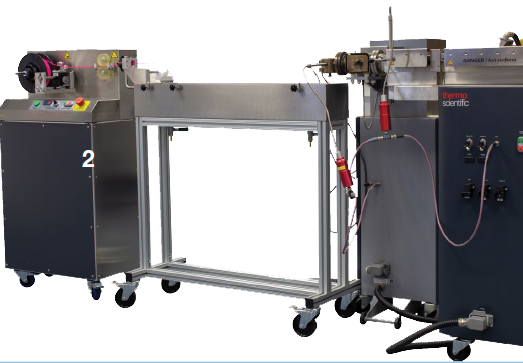

Thermo Scientiἀc™ HAAKE™ PolyLab Pilot-scale 3D Filament Production System

Use this system for lab-to-small scale process development and production. Figure 2 shows this system with:

- HAAKE PolyLab OS Rheomex PTW Twin-screw Extruder

- Thermo Scientiἀc™ Melt Pump for the OS Rheomex Extruder

- Filament spooler on a mobile bench

Reach material throughputs of up to 5 kg/h with this system that includes the ability to characterize new material compounds with mixer tests and capillary rheology.