Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Henniker Plasma

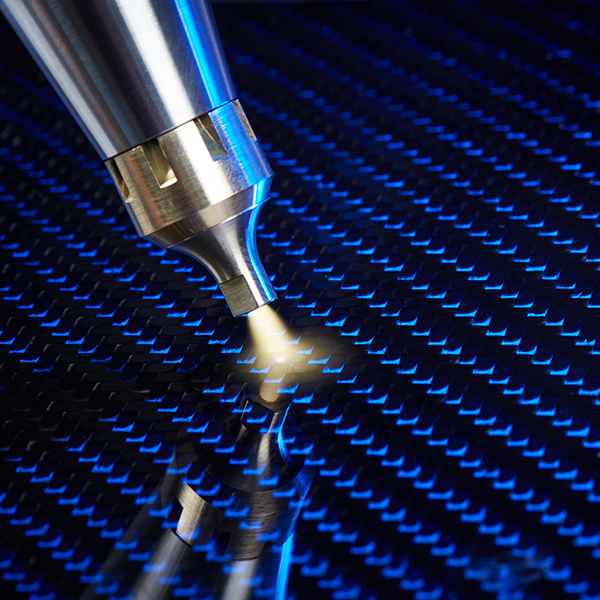

Henniker Plasma is a leading manufacturer of plasma treatment systems for cleaning, surface activation to improve adhesion, and functional nano-scale coating.

Their innovative plasma treatment equipment is trusted globally in both critical industrial manufacturing settings and by leading academic research groups where it is used in biomedical research, life sciences, energy storage, filtration, and many other areas of materials science in general. The equipment not only provides a solution to basic surface adhesion problems, but it can also impart specific functionality to medical devices, including permanent hydrophobic, hydrophilic, and low friction properties.

Henniker specialises in delivering surface engineering solutions that enable industries to achieve enhanced material performance and advanced technological capabilities. With a deep understanding of plasma technology and its applications, they offer a wide range of products and services designed to meet the unique requirements of various sectors.

Henniker is commited to helping you make informed decisions when choosing the right plasma treatment solution. With their expertise you’ll gain a deeper understanding of different plasma system options. Whether it’s for industrial applications, laboratories, or other specific requirements, they’re here to guide you towards finding the perfect match.