Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

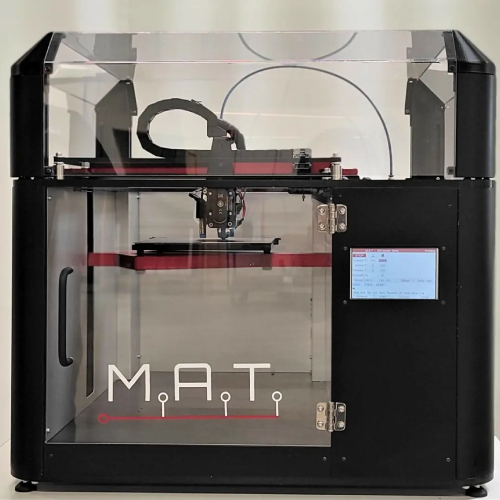

HPT-100 & HPT-200 | Plasma Surface Treatment

Introducing Henniker’s HPT-100 & HPT-200 Plasma Treatment Systems, cutting-edge, microprocessor-controlled benchtop units designed for optimal surface activation, cleaning, and modification of a diverse array of materials. Whether you’re looking for precise plasma etching or functional plasma coatings, these systems offer unmatched versatility and reliability. Elevate your surface treatment processes with the HPT-100 & HPT-200.

Introducing the HPT-100 & HPT-200 | Plasma Surface Treatment

The HPT-100 & HPT-200 are microprocessor controlled benchtop plasma treatment systems that are ideally suited to surface activation, cleaning and modification of a wide range of materials including polymers, metals, glass and ceramics.

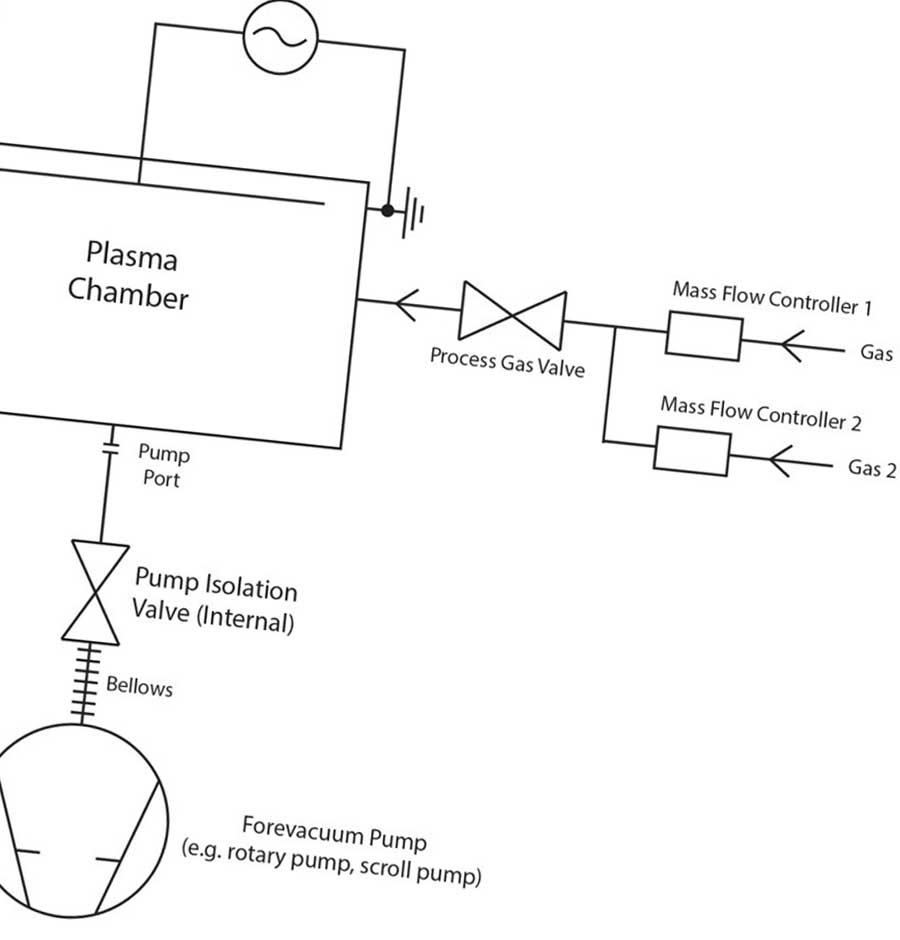

Available in fixed, single, or dual gas inlet versions and with onboard gas mixing manifold, the HPT-100/200 systems are able to handle a wide range of gases for optimised treatments, including air, oxygen, hydrogen, argon, nitrogen and many others.

TFT Colour touchscreen:

|

Each system is supplied with a 5.7-inch colour touchscreen which provides a rich, user-friendly interface. Variables such as gas flow rate, pressure, power level and plasma processing time can be freely set and then stored to produce a fully interlocked process cycle from a single key press. A handy status display and end-of-process audible alarm informs the user of every step in the process. |

Key Features

- Gas Inlet Versatility:

- Available in fixed, single, or dual gas inlet versions with an onboard gas mixing manifold to accommodate various gases like air, oxygen, hydrogen, argon, nitrogen, and more for optimized treatments.

- Optional vapour delivery inlet for liquid precursors, expanding application possibilities.

- Comprehensive Material Handling:

- Suited for diverse materials, including polymers, metals, glass, ceramics, PDMS, microfluidic devices, engineering polymers like PEEK, PTFE, metals, ceramics, and glass & optical devices.

- Process Control TFT Touchscreen:

- TFT color touchscreen interface (5.7-inch) for easy user interaction and setting adjustments.

- Allows setting and storing variables like gas flow rate, pressure, power level, and plasma processing time, streamlining the process into a one-keypress operation.

- Plasma Environment:

- HPT-100: 100mm diameter plasma process chamber in stainless steel with vacuum-compatible materials.

- HPT-200: Larger 150mm diameter plasma process chamber to accommodate more or larger samples.

- Henniker’s proprietary, high-stability HPS plasma generator continuously variable over 0-100W/0-200W power range for precise control, especially with delicate materials.

Key Benefits

- Versatility and Future-Proofing:

- Gas inlet options to suit budget and application, with the ability to add different options later, ensuring adaptability for evolving requirements.

- Reliable and Repeatable:

- Precision flow control and integrated pressure gauge ensure unmatched reliability and repeatability by reducing errors common in gas flow and type settings found in manual setups.

- User-Friendly and Efficient:

- Compact benchtop units that are easy to operate and navigate with the TFT interface.

- Quick treatment times, ensuring efficiency in your processes.

- Environmentally Friendly:

- No hazardous emissions, making it an eco-friendly choice for your workspace.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.