Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

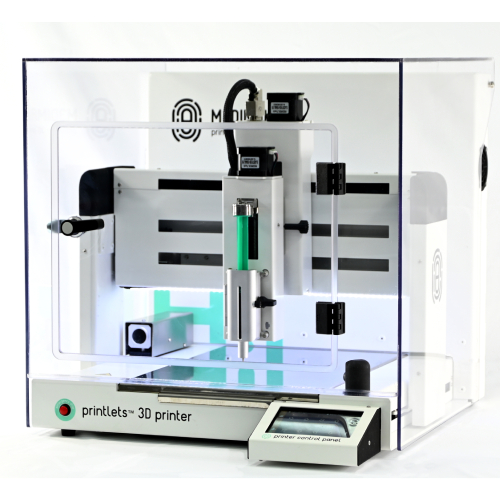

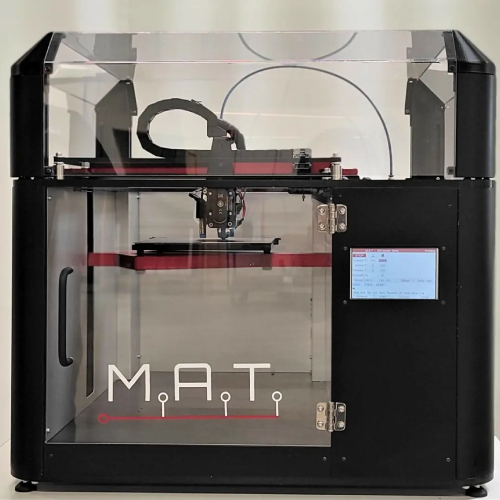

3DCeram – M.A.T. (Multi Additive Technology)

Introducing M.A.T. by 3DCeram, a groundbreaking ceramics printing technology in Canada. It extends 3D printing to advanced ceramics with precise control and versatile material compatibility. Enjoy efficiency, precision, and ease of use. M.A.T. also offers CNC machining and robocasting for post-processing. Ideal for Canadian researchers, M.A.T. combines two leading 3D extrusion technologies for prototype development and complex ceramics.

Introducing the 3DCeram – M.A.T. (Multi Additive Technology)

M.A.T. (Multi Additive Technology) by 3DCeram is Revolutionizing Ceramics Printing in Canada.

Traditionally, 3D printing has focused on plastics like PLA, ABS, and PETG. However, M.A.T. extends the capabilities of Fused Filament Fabrication (FFF) to include technical ceramics such as SiC, alumina, and zirconia, opening doors to innovative research opportunities.

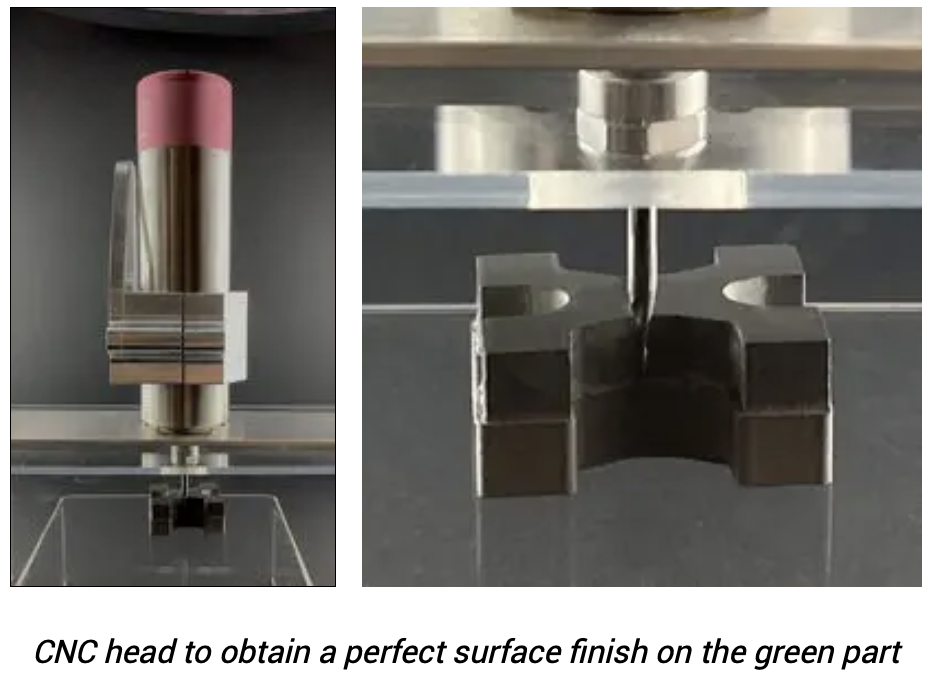

M.A.T. goes beyond standard FFF technology by offering two additional processes: CNC machining and robocasting.

CNC Machining/Milling:

The sturdy M.A.T. frame allows for quick head swaps. The transition from printing to CNC machining effortlessly, enhances surface finish, flatness, and resolution. This pre-sintering machining is cost-effective and efficient.

Robocasting:

Switch from FFF to robocasting with ease. While robocasting may have a coarser finish, M.A.T. lets you refine it through CNC machining. Customize your own slurry or use our ready-to-use slurry for robocasting.

The Ultimate Ceramic Research Tool:

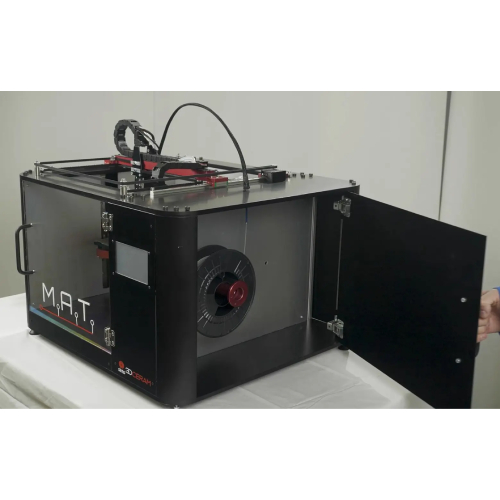

If you’re a Canadian researcher looking for versatility and flexibility in ceramics production, M.A.T. is your answer. Combining the power of two leading 3D extrusion technologies with green machining, M.A.T. is the ideal choice for prototype development and small-series production of complex ceramic parts.

Key Features

- Advanced Ceramics Printing: M.A.T. employs high-volumetric loading (around 50%) of fine ceramic powder within a thermoplastic matrix, offering precision in ceramic shaping.

- Dedicated Ceramic 3D Printing: Unlike traditional FFF processes, M.A.T. caters to the unique demands of ceramic filaments, which are brittle and have lower melting points.

- Temperature Control: M.A.T. ensures precise temperature management, critical for ceramics that soften at lower temperatures, to achieve exceptional results.

- Tailored Extrusion Mechanism: Its extruder motor and mechanism delicately handle ceramic filaments, maintaining torque for consistent extrusion through fine nozzles.

- Comprehensive Support: M.A.T. simplifies the complex nuances of ceramics printing, from abrasion-resistant materials to nozzle sizes, extrusion parameters, and stress reduction during shaping.

- Versatile Material Compatibility: M.A.T. handles a range of ceramic filaments including Silicon Carbide, Alumina, and Zirconia, as well as metal filaments like Titanium, Stainless Steel, and Copper.

Key Benefits

- Efficiency: M.A.T. (Multi Additive Technology) streamlines the intricate ceramics 3D printing process, saving time and resources.

- Precision: Achieve unmatched accuracy in your ceramic prototypes and small-scale production.

- Material Diversity: Expand your research horizons with various ceramic and metal filament options.

- Ease of Use: M.A.T.’s user-friendly interface and robust construction make it suitable for both novices and experts.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.