Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Heidelberg Instruments MLA300 THE MASKLESS ALIGNER FOR VOLUME PRODUCTION

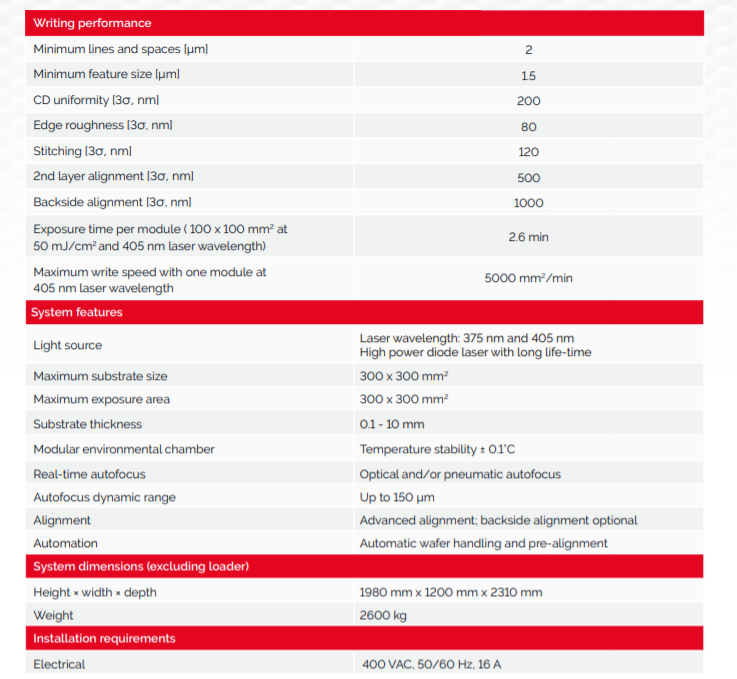

- Maximum exposure area: 300 mm x 300 mm

- Minimum feature size: 1.5 μm

- Minimum lines and spaces: 2 µm

- Maximum write speed: 5000 mm2/min (at 405 nm, with one module)

- Real-time autofocus

- Overview camera for fast alignment and inspection

- Front- and backside alignment

- Temperature-controlled environmental chamber

- Exposure wavelengths: 405 nm and / or 375 nm

Introducing the Heidelberg Instruments MLA300 THE MASKLESS ALIGNER FOR VOLUME PRODUCTION

The MLA300 is the industrial production version of the Maskless Aligner, which already has become a standard in Research & Development applications, rapid prototyping, and low-to mid-volume production. The MLA300 achieves high resolutions of 2 µm lines and spaces at the high throughput and high availability expected in production. It features full automation with wafer robot and load ports, and software specifically designed for the production environment to offer a simplified automated workflow.

At the same time, it features all the advantages associated with maskless lithography: Overheads and expense associated with the procurement of masks, and their handling, cleaning, and storage are eliminated.

Key Features

A Maskless Aligner for Industry

The MLA300 is based on the Heidelberg Instruments Maskless Lithography technology, which has become a standard in Research & Development applications, rapid prototyping, and low-to mid-volume production.

The MLA300 is the industrial production version of the Maskless Aligner, with outstanding specifications: It achieves high resolutions of 2 µm lines and spaces at the high throughput and high availability

expected in production. It features full automation with wafer robot and load ports, and software specifically designed for the production environment to offer a simplified automated workflow.

The Maskless Technology

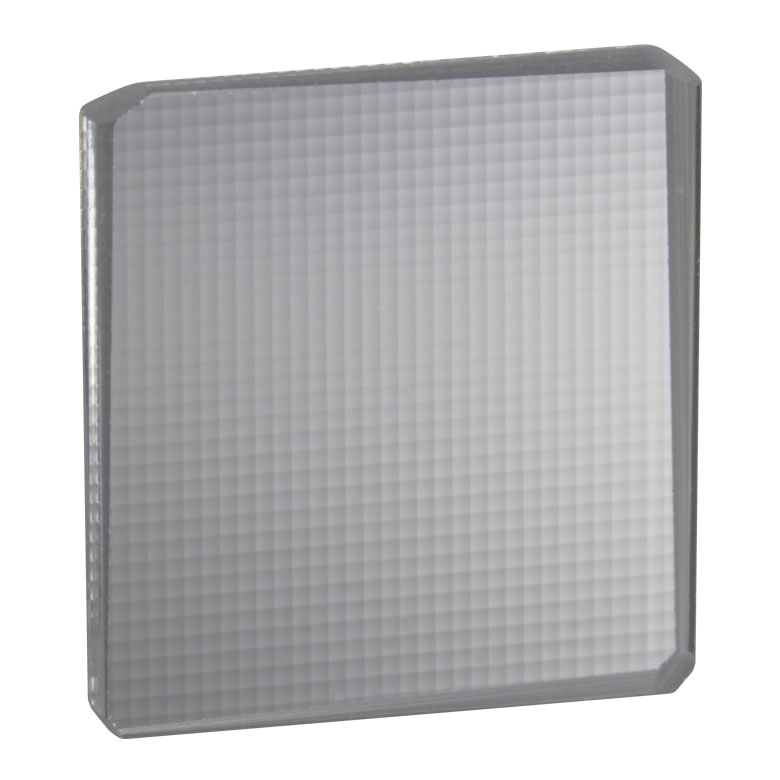

The Maskless Aligner technology uses a Spatial Light Modulator which essentially acts like a dynamic mask. It offers the flexibility to structure the most challenging substrates, allowing per-die pattern corrections (e.g. to react to distortions or process variations), and employs a real-time autofocus to follow substrate warp or corrugations. The non-contact exposure gives the system an unmatched durability and reliability

The overheads and expense associated with the procurement of masks, and their handling, cleaning, and storage are also eliminated. The system is designed for low total cost of ownership with its long-life

diode laser and no consumables requirements. The positioning system is based on a frictionless air-bearing table, which offers high speed and high-accuracy motion, while simultaneously optimizing durability and lifetime.

Applications

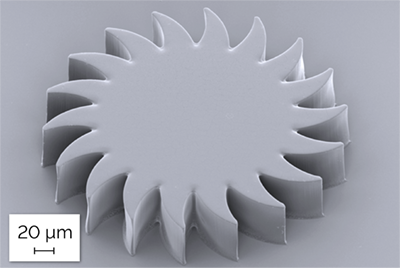

The MLA300 excels in application areas such as the production of sensors, sensor ICs, MEMS devices, discrete electronic components, analog and digital ICs, ASICs, Power electronics, OLED displays, as well as for advanced packaging applications.

Maximum Flexibility

The novel modular concept allows maximum flexibility for the MLA300, which can thus be tailored to the production task and facility requirements. The loader module can be configured to interface to existing substrate carrier or FOUP systems and ensures seamless integration to the production line.

The fully integrated exposure modules are available for a selection of wavelengths (375 nm or 405 nm) and with different resolution options. Multiple exposure modules can be mounted in the MLA300, either operating a single module optimized for the product and resist (wavelength, resolution or throughput), or operating multiple identical modules simultaneously for further increased throughput.

Key Benefits

The Maskless Aligner technology uses a Spatial Light Modulator which essentially acts like a dynamic mask. It offers the flexibility to structure the most challenging substrates, allowing per-die pattern corrections (e.g. to react to distortions or process variations), and employs a real-time autofocus to follow substrate warp or corrugations. The fully integrated exposure modules are available for a selection of wavelengths (375 nm or 405 nm) and with different resolution options. Multiple exposure modules can be mounted in the MLA300 for even higher throughput.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.