Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

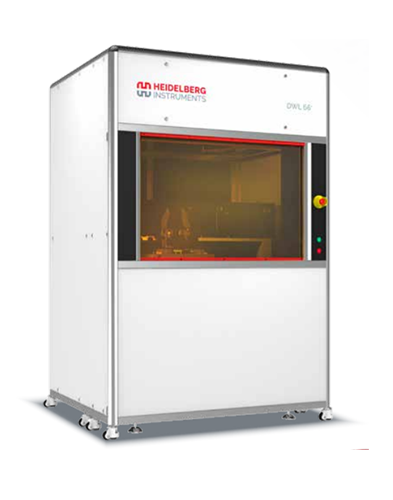

Heidelberg Instruments DWL 66+ THE ULTIMATE LITHOGRAPHY TOOL – THE SPECIALIST FOR GRAYSCALE MODE

- Maximum exposure area: 200 x 200 mm²

- Maximum substrate size: 9″ x 9″

- Multiple Write Modes

- Minimum feature size: down to 300 nm

- Maximum write speed (at 4 µm feature size): 2000 mm²/min

- Address grid down to 5 nm

- Grayscale exposure mode with up to 1000 gray levels

- Vector and Raster scan exposure mode

- Multiple data input formats

- Front- and backside alignment

- Climate chamber

- Two choices of laser wavelength (405 nm or 375 nm)

- Real-time autofocus system

- Scripting capability

- Integrated camera system for measurement and inspection

Introducing the Heidelberg Instruments DWL 66+ THE ULTIMATE LITHOGRAPHY TOOL – THE SPECIALIST FOR GRAYSCALE MODE

The DWL 66+ laser lithography system is an economical, high-resolution pattern generator for direct writing. The system features powerful options such as front- and backside alignment and a choice of 405 nm or 375 nm laser wavelength. Further advanced options include an absolute position calibration and an automatic loading system. A total of six different Write Modes are available, amongst them the High-Resolution Mode with a resolution of 300 nm. Notably, the DWL 66+ presents the ultimate performance in Grayscale exposure mode, from Standard to Professional levels: This versatile technique for the creation of complex 2.5D microstructures in thick layers of low-contrast positive photoresists is used for applications such as micro-lenses, DOEs, holograms (CGHs), and textured surfaces.

This highly flexible and customizable system can be specifically tailored to your application – the sophisticated capabilities of the DWL 66+ make it the essential lithography research tool in Life Science, Advanced Packaging, MEMS, Micro-Optics, Semiconductor and all other applications that require microstructures.

Key Features

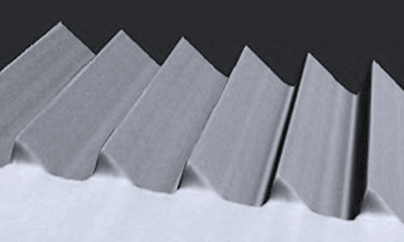

BLAZED GRATING

A diffraction grating patterned with DWL 66+. Both the angle of the sawtooth-like profile and the groove spacing are tuned to match the specific application requirements. Blazed gratings are key components of many optical instruments, such as monochromators and spectrometers used in sensors, communication systems and other tools.

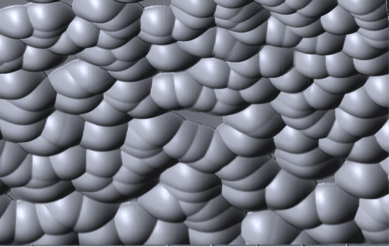

COMPOUND MICRO- AND NANOSTRUCTURES

“Moth eye” compound microlenses array replicated with nanoimprint technology shows DLW 66+ capabilities for 2.5D patterning. Texturing surfaces using grayscale lithography can control and modify their hydrophobicity, friction, haptics, and adhesion.

DIFFUSERS AND REFLECTORS

Retro-reflector structure was patterned using DWL66+. 2.5D micro-structures designed to control reflection or diffusion of light are used in light sources and illumination, like backlight units in LCD displays.

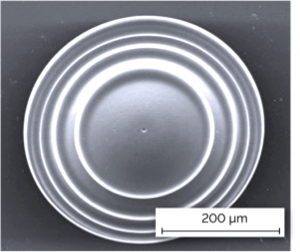

FRESNEL LENSES

Fresnel micro-lenses are still a crucial component in today’s micro-optics and opto-electronics. Originally invented to reduce mass and volume of lenses used in lighthouses, Fresnel micro-lenses manufactured by grayscale direct-write lithography are used in mobile devices, enabling ultra-light and compact powerful cameras that fit in our pockets.

HIGH-RESOLUTION WRITE MODE

The 300-nm-wide channel waveguide coupled to a ring resonator with a radius of 3 µm was written using the high-resolution write mode HiRes on the DWL 66+. Submicron waveguides, resonators and similar microstructures are used in optoelectronics to guide or study electromagnetic radiation. This design was created with the “Nanolithography Toolbox”, K.C. Balram et al., J. Res. natl. Inst.

MICROLENS ARRAYS

This array of pseudo-random concave microlenses is used as a diffusor. Such devices modify the light distribution of a point-like source, e.g. LED. For example, in mobile devices, a diffusor is used to ensure homogeneous illumination when taking a picture with a flash.

Key Benefits

A CHOICE OF GRAYSCALE CAPABILITIES

Grayscale lithography uses a low-contrast positive photoresist. The exposure intensity gradient transfers directly into exposure depth. The result after processing is a 3D topography on the microscale.

Whether standard, advanced or professional – the grayscale mode presents a powerful tool for the creation of complex topographies – for example for micro-optical components or MEMS

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.