Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

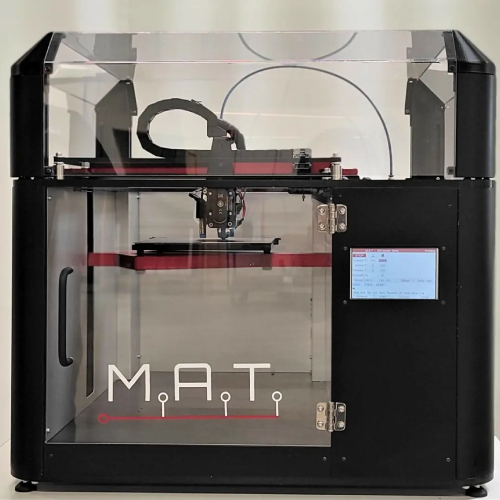

3DCeram Sinto

3DCERAM SINTO is a leader in the 3D Ceramic printing world. Created in 2001 in Limoges, with a site in Wallingford CT for the North American market , providing an unparalleled expertise in the technology of ceramic 3D printing. Using the unique laser stereolithographic technology, 3DCERAM SINTO has developed a complete offering to respond to their clients’ needs from materials development to the optimization of their 3D printer range for R&D innovation centers to large scale industrial manufacturers of technical ceramics.

For more than 15 years the company has developed a know-how in 3D printing, and offers its unique scientific expertise in:

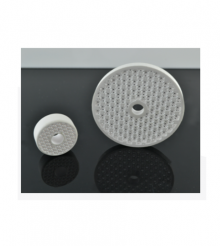

• Mastering 3D printing technologies with laser stereolithography (SLA),

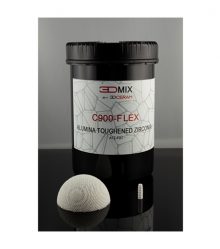

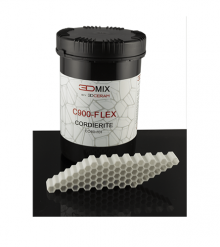

• A process to manufacture ceramic parts: zirconia, HAP, alumina.

• Ceramic slurries developed in-house by 3DCeramHighly qualified people (doctors, engineers, technicians, etc.) enable their expertise to be shared in order to offer the best 3D printing solutions.

• A process to manufacture ceramic parts: zirconia, HAP, alumina.

• Ceramic slurries developed in-house by 3DCeramHighly qualified people (doctors, engineers, technicians, etc.) enable their expertise to be shared in order to offer the best 3D printing solutions.