Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

3DCERAM C900 HYBRID

3DCERAM offer the C900 Hybrid in order to print a second, or more, material at the same time.

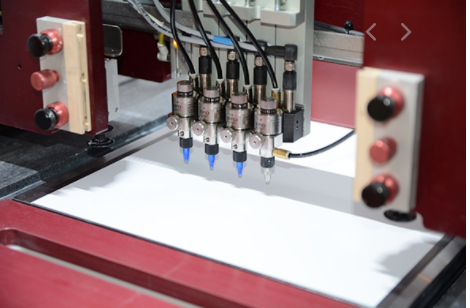

- The deposit of the second material can be adjusted according to your needs and specifications.

- Inside the system, several type of dispenser systems are possible up to 3 systems : from needle valve to micro dispensing system.

- Hybrid functions integrated in CPS software (one software to control printer and hybrid)

Introducing the 3DCERAM C900 HYBRID

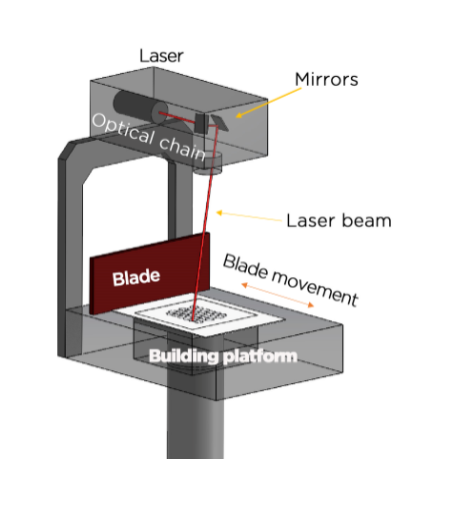

Printing Without Supports

Top-down stereolithography enables technology that can print without supports. The tray moves down as the part itself is built from the bottom-up. 3DCeram is able produce consistent parts with high precision and fine details.

The feeding of the printing material is done by a printing material is fed into a cartridge which is simply filled at the beginning of the printing cycle. It is possible to re-fill the cartridge during the printing cycle.

Key Features

3DCERAM offer the C900 Hybrid in order to print a second, or more, material at the same time.

- The deposit of the second material can be adjusted according to your needs and specifications.

- Inside the system, several type of dispenser systems are possible up to 3 systems : from needle valve to micro dispensing system.

- Hybrid functions integrated in CPS software (one software to control printer and hybrid)

Key Benefits

3DCeram ceramics are developed for use with the C900 Hybrid printer.

Indeed, their technical characteristics promote a regular feeding of the printer and allow to obtain homogeneous layers for a maximum quality of the products. They guarantee a level of quality recognized by the most demanding industries.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

| Approx. Dimensions | 1060 x 2250 x 2040 mm (LxPxH) |

| Build platform size | 300 x 300 x 100 mm |

| Approx. Weight | 1450 kg |

| Electrical requirements | 220-240 VAC / 50Hz |

| Electric power | 2 kW |

| Light source | UV Laser |

| Laser spot diameter | ~ 35 μm |

| UV Wavelength | 355 nm |

| Layer thickness | 0.010 – 0.125 mm |

| Optimal room temperature | 20-25°C |

| Maximum room temperature variation | 1°C/hour |

| Relative humidity | 50% |

| Compressed air | 6 bars dry |

| Hybrid option | Available |