Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

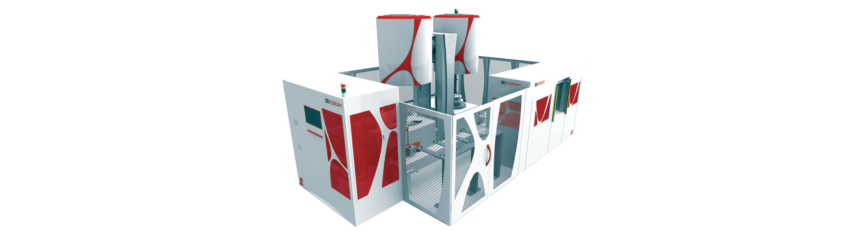

3DCERAM C900 FLEX

FOR SMALL SERIE AND PROTOTYPING

- 3 sizes of building platform : 100 x 300 mm, 200 x 300 mm and 300 x 300 mm

- First printer developed by 3DCeram, the C900

- FLEX gets the benefits of 15 years of know-how and optimization

- Print functional parts or small series

- SAM (Small Amount of Material) option : launch a fast printing run with only 100 mL of slurry

- Open parameters

- Ceramic printed parts have the same properties as those produced in conventional ways (moulding, machining and injection)

Introducing the 3DCERAM C900 FLEX

Printing Without Supports

Top-down stereolithography enables technology that can print without supports. The tray moves down as the part itself is built from the bottom-up. 3DCeram is able produce consistent parts with high precision and fine details.

The feeding of the printing material is done by a printing material is fed into a cartridge which is simply filled at the beginning of the printing cycle. It is possible to re-fill the cartridge during the printing cycle.

Key Features

First printer developed by 3DCeram, the C900 FLEX gets the benefits of 15 years of know-how and optimization.

To print functional parts or small series

Ceramic printed parts have the same properties as those produced in conventional ways (moulding, machining and injection)

Open parameters

3 sizes of building platform : 100 x 300 mm, 200 x 300 mm and 300 x 300 mm

Free link technology

Key Benefits

SAM (Small Amount of Material) option : to launch a fast printing run with only 100 mL of slurry

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

Dimensions Approx. ………………………………… 1060 x 2250 x 2040 mm (LxPxH)

Building platform size ……………………………… 300 x 300 x 100 mm

Weight ……….………………………………………….. 1450 kg

Electrical requirements ……………………………. 220-240 VAC / 50Hz

Electric power ……….………………………………… 2 kW

Light source ……………………………………………. UV Laser

Laser spot diameter ………..……………………….. ~ 35 μm

Wavelenght UV …….…………………………………. 335/405 nm

Layer thickness …………………………………….…. 0.010 – 0.125 mm

Room operating temperature …………..……….. 20-25°C

Room maximum temperature variation …..… 1°C/hour

Relative humidity ……………………………………. 50%

Compressed air …..…………………………………… 6 bars dry

Hybrid Option ………………………………………… Available