Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Heidelberg Instruments NanoFrazor Professional

INDUSTRIAL-GRADE THERMAL SCANNING PROBE LITHOGRAPHY TOOL WITH MULTI-TIP WRITE HEAD

- High-resolution

- Thermal Scanning Probe Lithography

- Non-invasive Lithography

- Precise Overlay and Stitching

- Unique Thermal Cantilevers

- IDecapede Module

- Laser Sublimation Module

- Vibration Isolation

- Low Cost of Ownership

- Compatibility with all standard pattern transfer methods: lift-off, etching, nanoimprint lithography

- In-situ Imaging immediate control of patterned structures

Introducing the Heidelberg Instruments NanoFrazor Professional

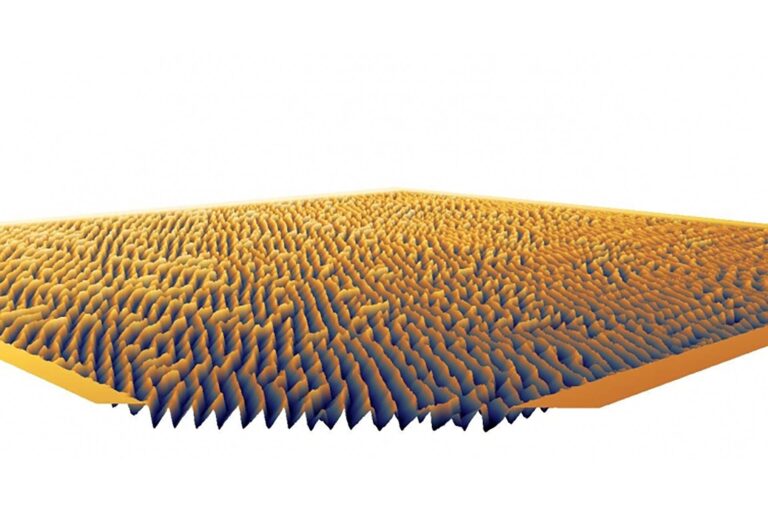

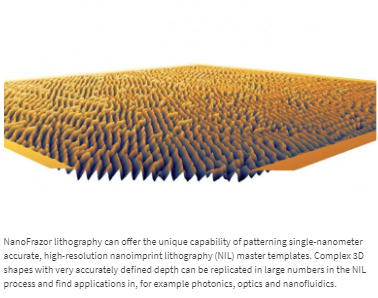

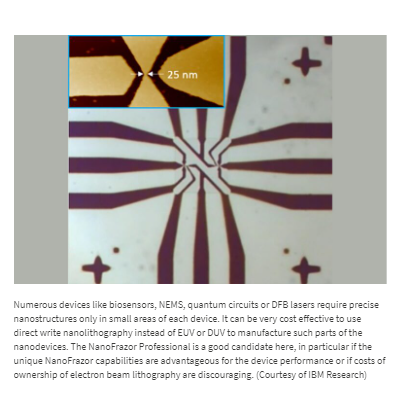

The NanoFrazor Professional is a platform that can be customized to meet individual requirements for industrial and prototyping applications. It combines all the unique NanoFrazor capabilities with a specially designed 8-inch wafer platform and an adapted high-speed piezo scanner for moving the tip. Various extensions can be added to increase speed, placement accuracy or automation. The NanoFrazor Professional is designed for process development of next generation semiconductor nodes, mastering for nanoimprint lithography, and manufacturing devices with nano-features in small areas.

With the direct laser sublimation module, nano- and microstructures can be seamlessly and quickly written into the same resist layer in a single fabrication step.

Key Features

High-resolution

Easy patterning of nanostructures even with complex geometries; min. lateral features 15 nm; vertical resolution 2 nm

Thermal Scanning Probe Lithography

New approach to nanopatterning enabling applications not otherwise feasible

Non-invasive Lithography

No damage from charged particles, no proximity effects, clean lift-off

Compatibility

With all standard pattern transfer methods: lift-off, etching, nanoimprint lithography, etc – knowledge resource and best practices available in our “Recipe Book”

In-situ Imaging

Immediate control of patterned structures

Precise Overlay and Stitching

Markerless overlay and stitching accuracy 25 nm specified, sub-10 nm overlay shown

Unique Thermal Cantilevers

Integrated microheater and distance sensor; easy to exchange and economical

IDecapede Module

10-tip write head for 10-fold increase in throughput for high-resolution patterning

Laser Sublimation Module

High-throughput exposure of coarse structures in the same exposure step; 405 nm wavelength CW fiber laser

Vibration Isolation

Three-layer acoustic and superior vibration isolation (> 98% @ 10 Hz)

Low Cost of Ownership

No need for cleanroom, vacuum pump or expensive consumables

Key Benefits

In-situ imaging enables two unique features: markerless overlay, and comparison of the written and target patterns during writing so that the parameters can be immediately adjusted. This approach, called closed-loop lithography, results in sub-2 nm vertical precision for 2.5D (grayscale) shapes of any complexity. Fast and precise control of a heated nanoscale tip enables innovation not otherwise feasible.

Laser Sublimation Module

High-throughput exposure of coarse structures in the same exposure step

Glovebox Integration

Customized solution in collaboration with MBraun with minimized vibrations for work in controlled atmosphere

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

|

|

|