Welcome to the latest issue of MC MATTERS, with news on Thermo Scientific™ extrusion and compounding systems, rheometry and viscometry, as well as information on seminars, expert tips and much more!

Request Quote

|

Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Welcome to the latest issue of MC MATTERS, with news on Thermo Scientific™ extrusion and compounding systems, rheometry and viscometry, as well as information on seminars, expert tips and much more!

|

► Visco❄holiday: Viscometer Gift

► Webinar: Methods of Viscosity Measurements

VISCO❄HOLIDAYAs a sign of customer appreciation and for the end of 2015, RheoSense presents a viscometer give-away and other prizes for all those completing our end-of-year survey. The following prizes will be awarded:

|

‘How to measure viscosity?’

‘How to measure viscosity?’We trace the historical development of viscosity and viscometers; starting with the fundamental principles established by Sir Isaac Newton and leading up to modern-day viscometry methods.

Sign up to attend the webinar and get an extra drawing for our promotion! Interested in learning more? Click the button below!

*Please note, all webinar sign ups will be given an extra entry on our Holiday Viscometer Giveaway!

Mesoscale Materials, Phenomena and Functionality

Presented by MRS Bulletin

November 18 | 12:00 – 1:30pm ET

Host: John Sarrao, Los Alamos National Laboratory

Attendance for this and all MRS OnDemand Webinars if FREE, but advance registration is required.

REGISTER NOW

The mesoscale domain where atomic granularity, quantization of energy, and simplicity of structure and function give way to continuous matter and energy, complex structures, and composite functionalities, represents a new scientific frontier. The November 2015 issue of MRS Bulletin explores some of the hallmarks of mesoscale materials science and highlights current and new research directions. This webinar will expand on some of the areas of mesoscale science explored in the articles in this issue of MRS Bulletin.

Speakers:

Integration of Computation and Experiment for Discovery and Design of Nanoparticle Self-Assembly

– Sharon Glotzer, University of Michigan

– Nicholas Kotov, University of Michigan

Instrumentation for In-Situ Mechanical Characterization: Nano to Meso

– Douglas Stauffer, Hysitron, Inc.

Bonus Talk:

Understanding and Manipulating Mesoscale Ferroic Domain Patterns

– Long-Qing Chen, The Pennsylvania State University

|

This webinar will introduce RheoSense’s automatic, high throughput viscometer, VROC® initium. Attendees will get the first sneak peek of the instrument and data.

Key Features Include:

Major Applications of VROC® initium Include:

|

||

|

|

|

||||||||||

|

Monitoring oil viscosity as a function of temperature and shear rate is essential for many reasons including: – Ensuring Oil Quality

– Oil Characterization Under Different Conditions – Detecting Oxidation (Decay) – Improving performance of engines & preventing mechanical failure – Reducing wear, inhibiting corrosion, improving sealing and cooling This webinar will cover the analysis and characterization of oils across temperature and shear rate ranges, along with the importance of such characterization. In addition, it will cover the estimation of high-temperature viscosity values utilizing room-temperature viscosity measurement and ASTM D341.

|

||

Date:

Tuesday, March 10, 2015

Time:

Session 1 (Europe)

2:00 p.m. (CET) /

1:00 p.m. (GMT/UTC)

Session 2 (North America)

11:00 a.m. EDT /

3:00 p.m. (GMT/UTC)

Duration:

1 hour

WHO SHOULD ATTEND:

Scientists, engineers and managers in research, process development and production, desiring a glimpse into the various areas of application for twin screw extruders in the pharmaceutical industry.

CONTENTS:

Hot Melt Extrusion (HME) has been advancing for a number of years for formulating active ingredients with low solubility. The HME process will be presented and discussed in detail using practical examples. The use of the extruder will be presented for moisture extrusion and granulation.

SPEAKERS:

Application specialists for the pharmaceutical industry

In this webinar, we present the capabilities of rheological tests to understand the basic flow behavior, as well as the complex application performance of formulations.

Click here for more information

Donna Hurley, National Institute of Standards & Technology

Roger Proksch, Asylum Research, an Oxford Instruments Company

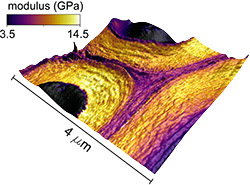

Nanoscale information on mechanical properties is critical for many advanced materials and nanotechnology applications. Atomic Force Microscopy techniques for probing mechanical properties of samples in the nanometer range have emerged over the past decades. In contrast to the large number of techniques for softer samples, few techniques are capable of measuring moduli in the 1-200 GPa range. One technique, Contact Resonance (CR), has proven to work very well in this range. CR methods operate in contact mode with dynamic excitation near a cantilever resonant frequency, enabling sensitive measurements over a wide range of materials. Moreover, analysis of the CR peak frequency and quality factor yields accurate, quantitative data on elastic modulus and viscoelastic damping.

Nanoscale information on mechanical properties is critical for many advanced materials and nanotechnology applications. Atomic Force Microscopy techniques for probing mechanical properties of samples in the nanometer range have emerged over the past decades. In contrast to the large number of techniques for softer samples, few techniques are capable of measuring moduli in the 1-200 GPa range. One technique, Contact Resonance (CR), has proven to work very well in this range. CR methods operate in contact mode with dynamic excitation near a cantilever resonant frequency, enabling sensitive measurements over a wide range of materials. Moreover, analysis of the CR peak frequency and quality factor yields accurate, quantitative data on elastic modulus and viscoelastic damping.

In this webinar, we’ll explain the basic concepts of measurements with different CR approaches including:

• Point spectroscopy

• Qualitative contrast imaging

• Quantitative mapping

We’ll also discuss practical implementation of contact resonance to a variety of samples and some of the pitfalls and artifacts you might encounter. Finally, we’ll present results on how CR methods have been used to improve understanding of systems such as:

• Composites

• Thin films

• Biomaterials

• Polymer blends

The nanomechanical characterization capabilities of CR methods, as you will come to learn, are an essential tool for the development, production, and in-situ monitoring of today’s and tomorrow’s materials.

Click here to register

Register Now8:00-9:00am PDT

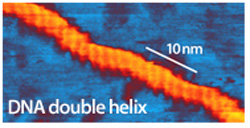

Register Now8:00-9:00am PDTYou may be a biologist new to the AFM or an AFM expert starting to study biology. When you first start out, using an AFM for biological applications can seem overwhelming. Although there are challenges for successful AFM in biology, we’ll show you it’s easier than you think!

Sample prep is a critical part of successful Bio-AFM. There are some basic principles that help insure success. However, life is complex and so are biological samples – with variations as large as the number of researchers. Thus, at the same time, you will need to be flexible – your samples may require a prep that is tweaked and tailored a bit to optimize your results. Working in liquid adds another challenge. In addition, the choice of measurement mode may not be obvious. Do I want to use tapping mode? Force curves? Contact Mode? Finally, there is a long list of commercial cantilevers available and choosing the best one can be like looking for a needle in a haystack.

The Webinar presents four case studies of typical biological samples

1. Imaging DNA in liquid – including routine helix resolution

2. Imaging living cells in liquid

3. Measuring Young’s modulus of living cells

4. Unfolding forces in Titin

In each case we will discuss sample prep, lever and measurement mode choice and follow up with data interpretation and cautionary examples of experimental artifacts. The goal of this webinar is to give you the confidence to repeat these experiments yourself and then extending them to fit your own research.

About the lecturer

Irene Revenko is one of the world’s leading experts in Bio AFM. She is a staff scientist at Asylum Research and has over 19 years of AFM experience. She initiated the first bio-classes at Asylum Research in 2002 and since then has taken many students from their first AFM measurements through cutting edge results.

WITec 3D Raman Imaging Meets AFM, SNOM and Profilometry Workshop. May 24th, 2013 – Université de Montréal

This workshop will give a detailed introduction to the operational principles and instrumental configurations relevant to confocal Raman and Scanning Probe Microscopy (AFM, SNOM, Pulsed Force Mode). Our Speakers will cover several aspects of Raman and SPM imaging and their fields of applications. An extensive system demonstration gives the participants the opportunity to see this knowledge applied using an alpha300 RSA (combined AFM & SNOM Confocal Raman Microscope).

Scientists interested in how to chemically identify and image the compounds of a sample at the highest spatial resolution are invited to participate. Typical research fields for confocal Raman imaging are nanotechnology, pharmaceutics and cosmetics, materials and polymer sciences, archaeology and geoscience, forensics, coatings, thin films and all fields where a clear identification of the distribution of chemical compounds is a necessity.

Program:

Friday, 24th May 2013

09.30 Welcome

09.45 Wei Liu – Introduction to Confocal Raman Imaging

10.15 Sylvain Cloutier – Hybrid Nanocrystal-based Heterostructures for Opto-Electronis

10.45 Klaus Weishaupt – 3D Raman Imaging Meets AFM, SNOM and Profilometry

11.30 Jean-Francois Masson – Characterization of photonics nanomaterials for plasmonic sensors

12.00 Lunch & Equipment Demonstration

The workshop is free of charge but it requires registration due to limited availability of places. In order to register, please contact Murielle Johnson at muriellej@aca.ca or 905-502-2088

Click here and download the May 24th 3D Raman Imaging Meets AFM, SNOM and Profilometry Workshop PDF for full program details.

Webinar date:

Tuesday April 16, 2013

Webinar Time:

Session 1 (Asia-Pacific) – 3:00 p.m. (CST)

Session 2 (Europe) – 2:00 p.m. (CEST)

Session 3 (North America) – 11:00 a.m. (EDT)

Webinar Duration:

45 minutes in length, followed by a question and answer period.

To register please click here

Brought to you by:

TARGET AUDIENCE

Scientists, engineers and managers in research, process development and production, desiring a glimpse into the various areas of application for twin screw extruders in the pharmaceutical industry.

CONTENTS

Hot Melt Extrusion (HME) has been advancing for a number of years for formulating active ingredients with low solubility. The HME process will be presented and discussed in detail using practical examples. The use of the extruder will be presented for moisture extrusion and granulation.

SPEAKERS

SPEAKERS

Application specialists for the pharmaceutical industry.

LANGUAGE

English

DATE

Tuesday April 16, 2013

TIME

Session 1 (Asia-Pacific) – 3:00 p.m. (CST – China Standard Time)

Session 2 (Europe) – 2:00 p.m. (CEST – Central European Summer Time)

Session 3 (North America) – 11:00 a.m. (EDT – Eastern Daylight Time)

WEBINAR DURATION

45 minutes in length, followed by a question and answer period.