Description

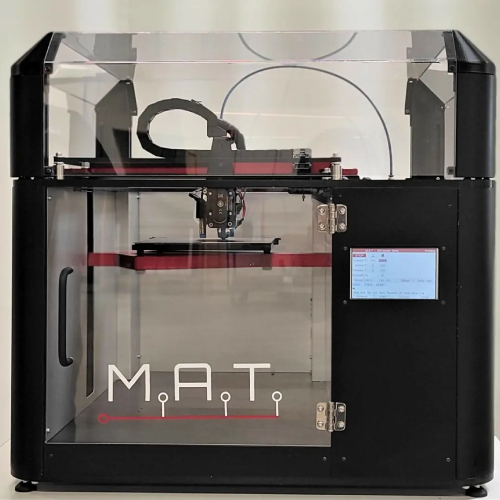

Apium Additive Technology, a leader in high-performance polymer processing, sets a new standard in material extrusion technology with the introduction of the P400 3D printer. The new P400, which extends the company’s industrial 3D printing portfolio, delivers outstanding layer adherence powered by its next-generation Adaptive Zone Heating System (AZHS), resulting in maximized print part strength and quality.

Apium P400’s Features and Benefits:

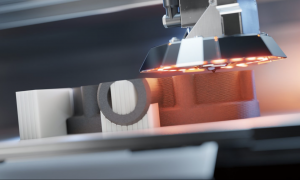

Next Generation Adaptive Zone Heater:The patented Adaptive Heating System delivers outstanding layer adhesion, resulting in maximized printed part strength and quality. Equal material properties in all directions can be expected, like conventionally manufactured parts.

|

|

Energy Efficiency:Due to the adaptivity of the zone heater, printing large parts as well as small geometries avoids the disadvantages of heated build chambers such as time and energy-consuming heating and cooling of the entire build volume.

|

|

Multi-Material Processing:The Apium P400 provides a platform for multiple tools, which can process various materials according to their requirements. Using the Independent Dual Extrusion System, the production capacity can be doubled or materials of different properties can be processed in one printing session. High-performance polymers as well as technical polymers or compounds can be stored and preconditioned in the integrated dryer for an enhanced print result. |

|

Robust, Reliable and Organized:All components have been designed for continuous operation. High-quality linear rails and servo motors ensure high print quality and low maintenance requirements. Moreover, tracking and switching the nozzles and their dedicated materials can be done seamlessly. Switched nozzles are stored comfortably in the integrated tool drawer, while the printer remembers the matching of the nozzle and material. |

|

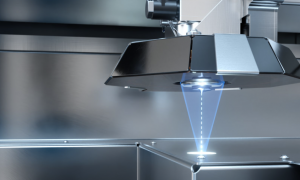

Process Integrity:Automatic bed leveling and sensors for monitoring the print process are essential for smooth printing. Successful multi-material prints require a precise print head alignment, which is achieved by an integrated optical calibration system. In addition, the integrated software tracks the status of consumables and maintenance parts. |

|

Process Documentation:All important print process parameters are automatically recorded in a protocol. The user administration provides easy operation management and tracking.

|

|

User friendly:The integrated software is specially adapted to the P400 printer hardware and is proven to process high-performance polymers. The status of the printer can be checked at any time on-site and via remote access. |

|

Open System:The Apium P400 is an open platform. Therefore, there are no restrictions on using custom materials or slicing software of any kind. Self-developed print tools can be easily integrated as well. |

|

Technical Support:With experience in processing high-performance polymers for almost a decade, Apium offers the most comprehensive service and support. Apium p400 Manufacture |