Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Apium Filaments – Medical PEEK

- Mechanical properties similar to human bone

- Biocompatible

- Radiolucent

- Low heat conductivity

- Good chemical resistance

- High temperature resistance

- Lightweight

- Excellent wear resistance

- Good fatigue resistanc

Introducing the Apium Filaments – Medical PEEK

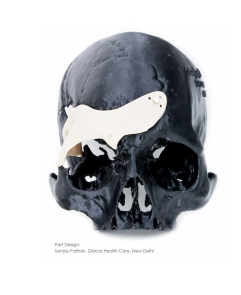

PEEK offers optimum properties for in-vivo applications in many aspects. In comparison to a titanium based implant, a PEEK implant is appreciably similar to the human bone in mechanical stiffness and elasticity thus can easily mechanically conform as the bone exercises internal motion. Since this material is radiolucent, it is suitable for radiological diagnostics and therapeutic radiation technology. Thanks to its insulating properties, the material is also less susceptible to temperature effects than its metal substitute materials.

Key Features

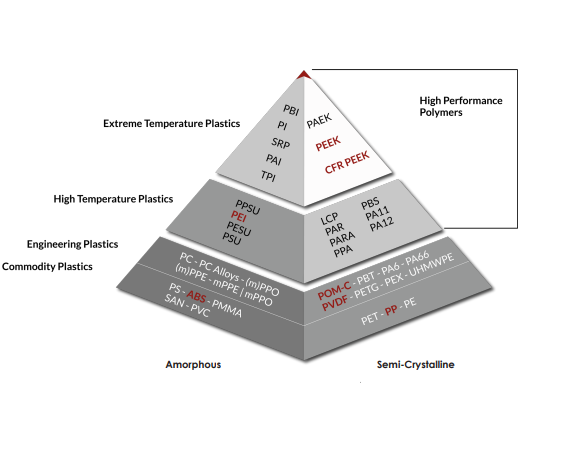

Semi-Crystallinity of PEEK

PEEK is a semi-crystalline material. Semi-crystalline materials have distinct characteristics compared to amorphous materials. Semi-crystalline materials have well-defined melting point, good chemical, fatigue and wear resistance. Proper attention must be paid to the temperature control during printing to ensure it is regulated well to produce parts of consistent crystallinity with good properties.

Apium P220 Series 3D printers allow the printing of PEEK parts with 29-32% crystallinity, the closest ratio in the 3D printing industry to 35% crystallinity of injection moulded PEEK parts.

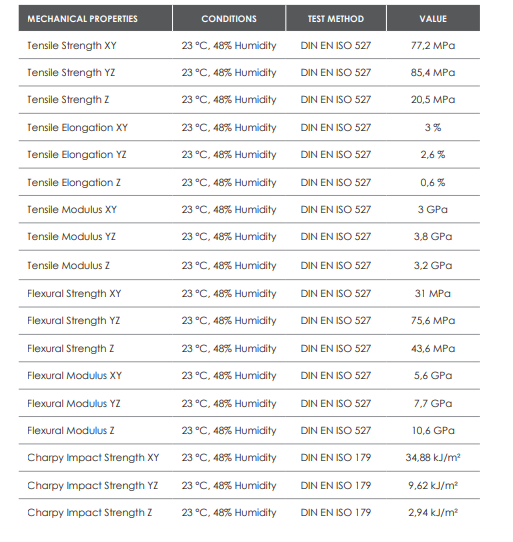

Characteristics of 3D Printed Semi-Crystalline PEEK

The professional PEEK 3D printers of Apium are capable of processing medical grade PEEK filaments with the highest quality in 3D printing industry.

Characteristics of 3D printed PEEK with Apium`s technology:

- Mechanical properties similar to human bone

- Biocompatible

- Radiolucent

- Low heat conductivity

- Good chemical resistance

- High temperature resistance

- Lightweight

- Excellent wear resistance

- Good fatigue resistanc

Key Benefits

In addition, the technology can be applied to the manufacture of surgical tools that come in any contact with the patient and therefore require medical certification.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Related products

-

Improve your print quality with dry filament

- Stronger Prints

- Energy saving

- High Capacity

- Scheduled Drying

- Absolute Silence

-

Apium P400 is the most flexible platform for processing High Performance and Engineering Polymers. Apium P400 enables one to experience a new level of additive manufacturing with its exceptional new features like Next Generation Adaptive Zone Heater, Energy Efficiency, Multi-Material Processing capability, and much more.

-

- Ø1,75 mm – High stiffness

- high thermal resistance

- high chemical resistance

- bio inert

- low warping

- tight dimensional tolerances

- low weight

- easy to remove support

- post treatment possible

-

- Filament Extruder X 1EA

- Hot-Melting Pneumatic Dispense X 1EA

- -4-60°C (cooling/heating)

- Ultrasonic Sensor + 1OOTPI Fine Adjust Screw I Fork Sensor

- 720p HD Camera

- C02 Incubator (C02 5%, 37°C, Humidity 80%)

- Syringe Pneumatic Dispense X 5EA + NFC Tagging System 1EA