Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Apium Specialty Filaments – PEEK

- High mechanical strength

- Good chemical resistance

- High temperature resistance

- Flame Retardant

- Lightweight

- Excellent wear resistance

- Good fatigue resistance

Introducing the Apium Specialty Filaments – PEEK

PEEK offers optimum properties for in-vivo applications in many aspects. In comparison to a titanium based implant, a PEEK implant is appreciably similar to the human bone in mechanical stiffness and elasticity thus can easily mechanically conform as the bone exercises internal motion. Since this material is radiolucent, it is suitable for radiological diagnostics and therapeutic radiation technology. Thanks to its insulating properties, the material is also less susceptible to temperature effects than its metal substitute materials.

Key Features

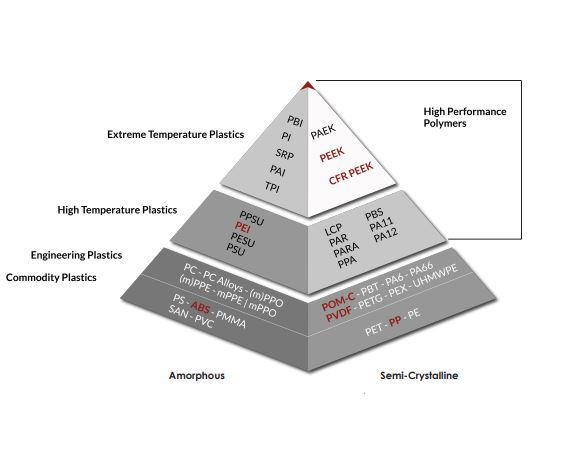

Semi-Crystallinity of PEEK

PEEK is a semi-crystalline material. Semi-crystalline materials have distinct characteristics compared to amorphous materials. Semi-crystalline materials have well-defined melting point, good chemical, fatigue and wear resistance. Proper attention must be paid to the temperature control during printing to ensure it is regulated well to produce parts of consistent crystallinity with good properties.

Apium P220 Series 3D printers allow the printing of PEEK parts with 29-32% crystallinity, the closest ratio in the 3D printing industry to 35% crystallinity of injection moulded PEEK parts.

Characteristics of 3D Printed Semi-Crystalline PEEK

The professional PEEK 3D printers of Apium are capable of processing medical grade PEEK filaments with the highest quality in 3D printing industry.

Characteristics of 3D printed PEEK with Apium`s technology:

- High mechanical strength

- Good chemical resistance

- High temperature resistance

- Flame Retardant

- Lightweight

- Excellent wear resistance

- Good fatigue resistance

Key Benefits

Aerospace

PEEK is your lightweight material solution where manufacturing costs, durability in harsh environments and processing flexibility play a significant role. It offers great benefits for landing gear hubcaps, aircraft door handles, cable ties, composite fasteners, as housing for fire prone components and many more applications.

Automotive

PEEK exhibits an excellent combination of strength, durability and heat resistance. PEEK is the material solution where system weight, energy efficiency and a wide range of operating temperatures (-196°C to 260°C) play a significant role in your operations.

Oil & Gas

PEEK is the material of choice for your oil and gas applications which require high quality equipment and tool systems to extreme temperatures, corrosive fluids and gases, and high pressures. For antenna sleeves, valve seats, electrical connectors, primary seals, impellers and many more system components, benefit from the outstanding characteristics of PEEK.

Semiconductors and Electronics

For the two main properties requirements -electrical insulation and mechanical function- of your electronics applications being contact sockets, insulators, wafer carriers, chemical cleaning systems, etc., PEEK is the material of choice with its outstanding properties.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Related products

-

In-situ 4D Fabricating The World’s First Z-Axis Curved Surface Fabricating Bio-Hyperspace Creation Sterilized Environment : H14 HEPA Filter, UV Lamp Diverse Material Usage All US FDA-Approved Materials : Bioinks, Biopolymers, Ceramics, etc. High Accuracy High-Precision Step-Motor & Temperature Control User-Friendly Interface LCD Touch Screen, Android OS, Wi-Fi, Remote Monitoring -

- Filament Extruder X 1EA

- Hot-Melting Pneumatic Dispense X 1EA

- -4-60°C (cooling/heating)

- Ultrasonic Sensor + 1OOTPI Fine Adjust Screw I Fork Sensor

- 720p HD Camera

- C02 Incubator (C02 5%, 37°C, Humidity 80%)

- Syringe Pneumatic Dispense X 5EA + NFC Tagging System 1EA

-

- Ø1,75 mm – High stiffness

- high thermal resistance

- high chemical resistance

- bio inert

- low warping

- tight dimensional tolerances

- low weight

- easy to remove support

- post treatment possible

-

- High Stiffness

- Good Wear Resistance

- High Temperature Resistance

- Good Chemical Resistance

- Lightweight

- High Compressive Strength

- Good fatigue resistance