Next Generation Solutions for Wireless Communication Systems

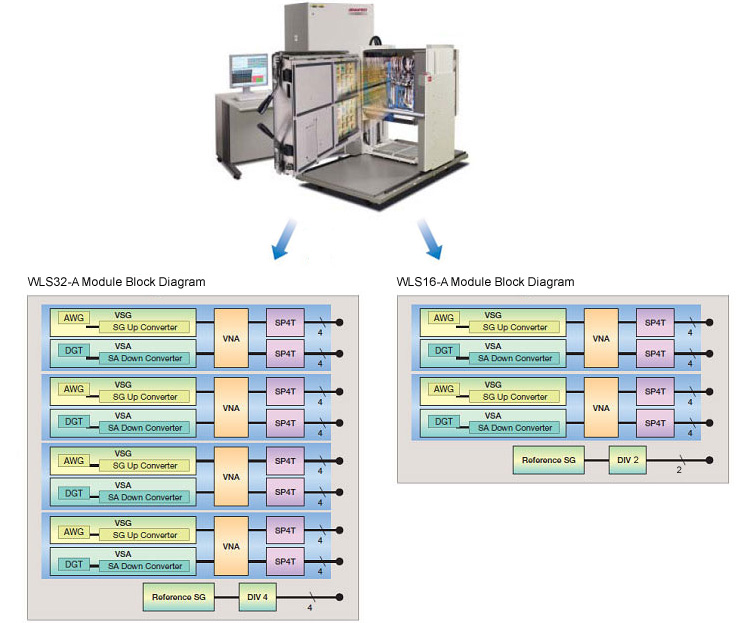

ATE Industry’s First Fully Integrated Single Module with 4-unique RF Vector Signal Generators and Analyzers (WLS32-A Module)

- High-Performance VSG and VSA Instrumentations Supporting Complex Modulation Densities up to 80MHz Bandwidth

- Fast Test Times Achieved with Fast Settling Synthesizer Switching

- Highest Industry RF Port Density (32 per module and scaleable to 128) for Today’s and Tomorrow’s Multi-DUT MIMO and Transceiver Applications (WLS32-A)

- For Low Cost small system, Half RF Port Density (WLS16-A)

- High-Speed & High Carrier to Noise Ratio Synthesizer Modes to Address Production and Characterization Solutions

- Integrated Low-Noise, Low-Jitter Programmable Reference Signal Generator for Crystal (TCXO) Reference

- Internal Highly Linear 2-tone Combiner to Produce > +28dBm (@2.2GHz, -12dBm) Output IP3 to Device

- Lowest COT Achieved with Quad-DUT Native Capability (Parallel Source and Measure)

CMOS Image Sensor Test Solution

The T2000 CMOS Image Sensor Test Solution is a single solution for evaluation and production testing of advanced CMOS image sensors with high-speed interfaces up to 3 Gbps. This highly parallel system uses concurrent hardware operation, a fast IP engine, a high-speed bus and reduced shot counts to provide users with one of the industry’s lowest cost of test.

Flexible support for multifunction image sensors

CMOS image sensors are now incorporating functions such as AD/DA and other SoC circuits. With its modular architecture, the T2000 can achieve the optimal configuration to test these complex devices while delivering low cost of test.

The system’s high-speed image-capture interface supports a variety of CMOS image sensors including mobile, DSC, DSLR, CAM and industrial CIS. In addition, the large dual-bank memory module enables simultaneous storage and transfer of data to the image-processing engine, minimizing test times.

The system is available in two versions:

1.2-Gbps CMOS Image Capture (1.2GICAP) Module

- Image Capture input:

Serial data: 1.2 Gbps, 4 lanes x 4 channels

・1.2 Gbps for MIPI D-PHY and sync code mode (Custom S-LVDS)

Parallel data: 200 M pixels/s, 16 bits x 4 channels - Capture memory: 128 M pixels x 2 banks

Maximum frame averaging number up to 256 frames (hardware averaging)

3-Gbps CMOS Image Capture (3GICAP) Module

- Image Capture input:

Serial data: 1.2 Gbps, 4 lanes x 4 channels

? 1.2 Gbps for MIPI D-PHY and sync code mode ?Custom S-LVDS?

Parallel data: 200 M pixels/s, 16 bits x 4 channels - Capture memory: 128 M pixels x 2 banks

Maximum frame averaging number up to 256 frames (hardware averaging)

Faster Processing for Higher Throughput

With its high-speed quad processors for image-capture data analysis, Advantest’s new image processor engine (IPE2) significantly reduces test times, especially for higher pixel CMOS image sensors.

Light Source and Large User Area Delivers Higher Parallelism

at a Low Cost of Test

The module’s ultra-high-volume, simultaneous measurement capability enables uniquely high productivity and a significant cost savings for image-sensor testing. Most importantly, the optimized, uniform light source and large user area enable highly parallel testing of ultra-high-density and high-performance devices.

- 440 mm probe card and 2048-channel frog unit (pogo interface)