Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

The NanoFlowSizer inline and real-time measurement in flow

- Low control over the production process

- Interruption of the production flow every time conditions are changed

- Need for laboratory analysis

- Impossibility to carry out Continuous Manufacturing (24-hour)

- Long time for analysis (10 min – hours)

- Variations in product quality due to absence of full process control

- Reduction in analysis time >90%

- Better process understanding promoting innovation

- New possibilities to study particle size dynamics in real time

- Reduction of production time with 1-3 days per batch

- Significant reduction in batch rejection saving € 0.2- 2M per manufacturing eve

Introducing the The NanoFlowSizer inline and real-time measurement in flow

The need for inline particle sizing

Nanotechnology, the design, synthesis, characterization and application of material and devices on the nanometre scale, is revolutionizing many technology and industry sectors: vaccines, medicine, energy, food, inks…

Physical, chemical and biological properties at the nanoscale are completely different from properties of bulk matter.

Key Features

Restrictions in nanoparticle analysis:

- Low control over the production process

- Interruption of the production flow every time conditions are changed

- Need for laboratory analysis

- Impossibility to carry out Continuous Manufacturing (24-hour)

- Long time for analysis (10 min – hours)

- Variations in product quality due to absence of full process control

- Reduction in analysis time >90%

- Better process understanding promoting innovation

- New possibilities to study particle size dynamics in real time

- Reduction of production time with 1-3 days per batch

- Significant reduction in batch rejection saving € 0.2- 2M per manufacturing eve

Current limitations

- Batch rejection

- Interruption of production process

- No continuous manufacturing

- Long time for analysis

- Limited performance

- Low control over production process

Lead to: Economic losses due to lack of solutions!

Key Benefits

A unique nanoparticle sizer: the NanoFlowSizer

The importance of particle size monitoring

The capacity of nanoparticles to carry out their function is dependent on their size as well as size distribution, which are directly related to efficacy and safety (for patients in pharma applications).

Since the behavior of particles at the nanoscale depends highly on these properties, their control is paramount to the entire development and manufacturing process of nanoparticle products.

Uncompromised monitoring

Pharma industry demands complete control over production processes of their high-quality products that need to comply with stringent regulations and demands, which costs $1 million/day1. They thus require sophisticated, highly efficient Process Analytic Technologies (PAT).

However, there is a lack of such PAT solutions for monitoring particle size and size distribution in the nanoscale regime, hindering nanoparticle applications from reaching full potential.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

Nanoparticles and their applications

Nanoparticles are natural and synthetic particles with a size in the 10-9 m range (1-1,000 nm). Due to their small size they have a large surface area in relation to their volume, conferring them special properties.

Nanoparticles are present in many of the items in our everyday life, such as transparent sunscreens or scratchproof glasses. Of special interest for the pharmaceutical industry, nanoparticles are used under different formulations, such as engineered drug delivery systems targeted to disease cells, reducing damage to healthy ones.

How this analyzer is different

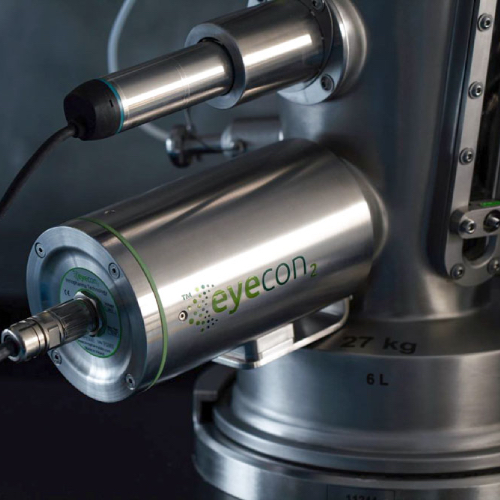

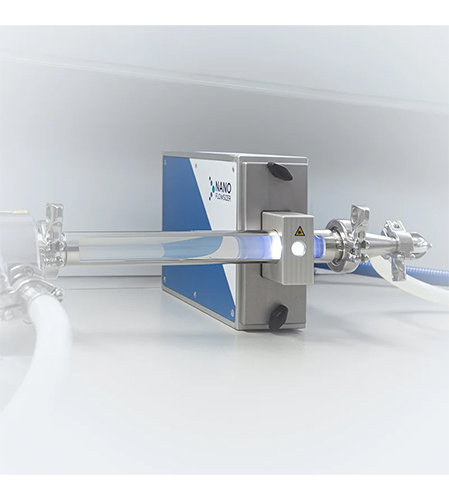

NanoFlowSizer (NFS) is a new non-invasive nanoparticle size analyzer developed by InProcess-LSP, the only one capable of carrying particle size and size distribution measurement for non-solid products inline, at the production flow, with no need to extract or treat a sample.

Results every 10 sec

With the NanoFlowSizer, nanoparticle sizing takes place within 10s, enabling continuous real-time in flow analysis.

Continuous, real-time nanoparticle size characterization

The NanoFlowSizer is a new innovative system for continuous, real-time nanoparticle size characterization of colloidal systems, nanosuspensions, nanoemulsions and other dispersed nanoproducts directly in manufacturing processes (inline) or in a laboratory setting (offline).