Date: June 20, 2025

Time: 10:00 AM Onwards

Venue: McGill University – Room 103, Rutherford Physics Building

Address: 3600 University Street, Montreal, Quebec, Canada H3A 2T8

Event Overview:

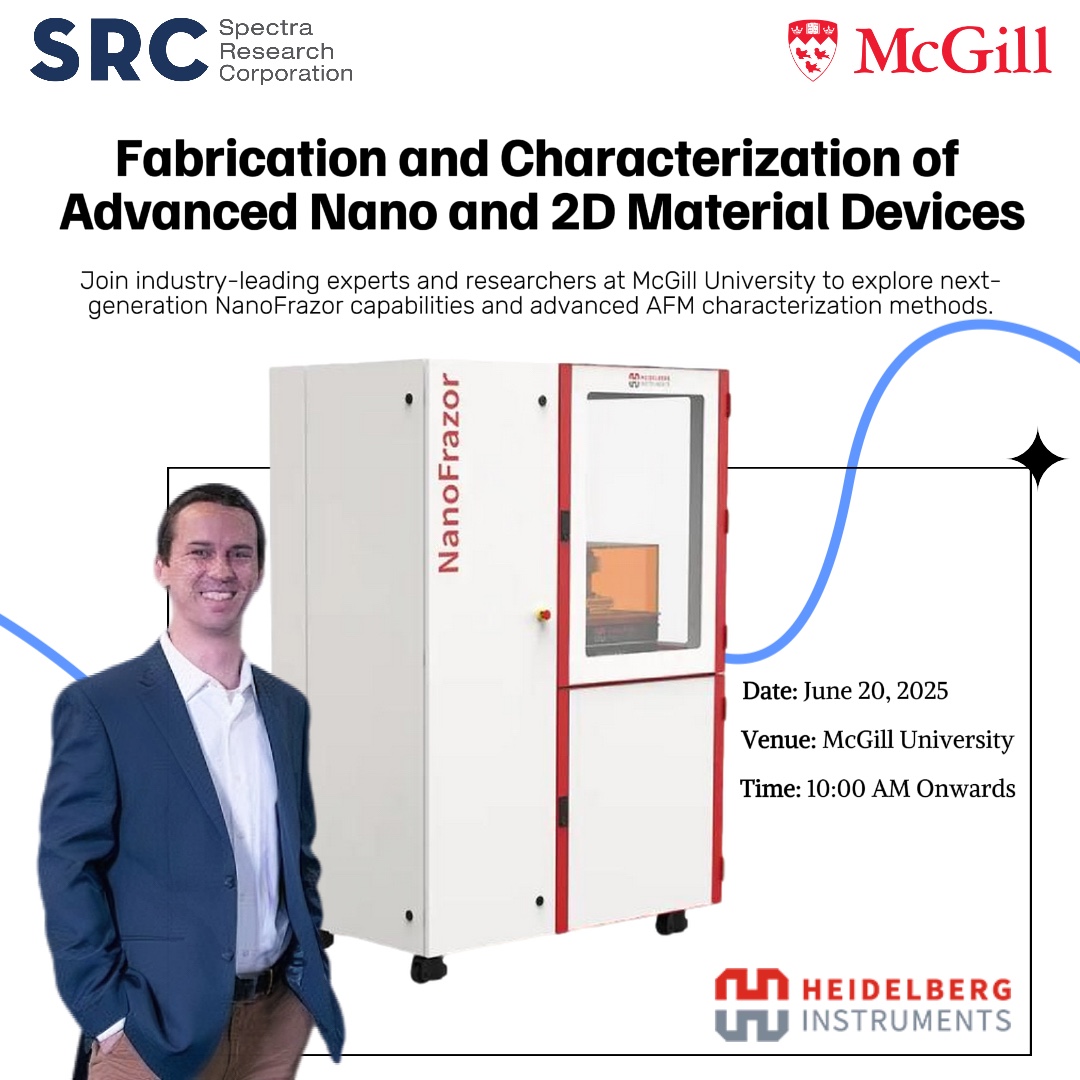

Spectra Research Corporation (SRC) in collaboration with Heidelberg Instruments invites you to an exclusive seminar and hands-on workshop focused on cutting-edge nanofabrication techniques and characterization methods for advanced nano and 2D material devices. Join industry-leading experts and researchers at McGill University to explore next-generation NanoFrazor capabilities and advanced AFM characterization methods.

Agenda

Morning Session:

- 10:00 AM – 10:15 AM: Facility Introduction by Dr. Zhao Lu

- 10:15 AM – 10:30 AM: SRC and Vendor Introduction by Serge Dandache (SRC)

- 10:30 AM – 11:15 AM: Presentation by Dr. Nicholas Hendricks (Heidelberg Instruments)

Topic: Fabrication of Advanced Nano and 2D Material Devices – Utilizing Next Generation NanoFrazor Capabilities - 11:15 AM – 11:30 AM: Coffee break with some Donuts!!

- 11:30 AM – 12:00 PM: Presentation by Sean Chen (McGill University)

Topic: Probing the Persistent Photoresponse in WS₂ using Kelvin Probe Force Microscopy - 12:00 PM – 1:00 PM: Lunch Break – Pizzas and Drinks

Afternoon Workshop Sessions (Cleanroom Demo):

- Session 1: 1:00 PM (Max 5 participants)

- Session 2: 1:45 PM (Max 5 participants)

Note: Each workshop session is limited to a maximum of 5 participants. Please register in advance and indicate your preferred slot (First come, first served basis).

Keynote Speakers

Dr. Nicholas Hendricks

Innovation Manager, Heidelberg Instruments Nano, Zürich, Switzerland

Nicholas specializes in next-generation nanolithography, with extensive experience in polymer science and advanced fabrication techniques. His expertise includes direct-write lithography methods for nanoelectronics, photonics, molecular sensing, and quantum computing applications.

Talk Highlights:

- Overview of Thermal Scanning Probe Lithography (t-SPL) with Heidelberg’s NanoFrazor for precise fabrication of nano and 2D material devices

- Benefits of NanoFrazor for direct-write nanolithography without charged particle damage

- Application examples including nanowires, quantum devices, and 2D material electronics

- Latest advancements: parallelized large-area patterning and automated nanofabrication

Sean Chen

Master’s Student, Department of Physics, McGill University

Working under Prof. Peter Grutter, Sean focuses on electrical properties of two-dimensional materials and optoelectronic devices, employing atomic force microscopy techniques such as Kelvin Probe Force Microscopy to study persistent photoconductivity in transition metal dichalcogenides.

Talk Highlights:

- Understanding persistent photoconductivity in WS₂ flakes using Kelvin Probe Force Microscopy

- Time-resolved studies of surface potential and photocurrent

- Investigations on the effects of illumination intensity, wavelength, doping, and flake thickness

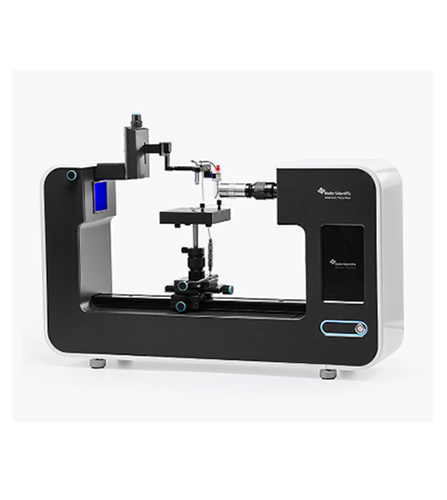

Hands-On Demo: NanoFrazor – Thermal Scanning Probe Lithography

Experience a live demonstration of Heidelberg’s NanoFrazor Thermal Scanning Probe Lithography System, showcasing its unique capabilities including:

- High-resolution, markerless overlay and sub-2 nm vertical precision

- Real-time in-situ imaging

- Versatile modular platform suitable for quantum devices, photonics, biotechnology, and MEMS

- Integrated Direct Laser Sublimation (DLS) for high-speed micro patterning

Who Should Attend?

- Researchers and professionals in nanoelectronics, semiconductor fabrication, and materials science

- Graduate students in physics, chemistry, and engineering

- Industry professionals involved in advanced electronic device fabrication and characterization

Register Today!

Don’t miss this opportunity to deepen your knowledge, network with experts, and gain practical insights into cutting-edge nano and 2D material research and fabrication techniques.

For inquiries or workshop registration, please contact us at:

📧 info@spectraresearch.com | 📞 905-890-0555

We look forward to seeing you at McGill University!

HORIBA Scientific has 200 years of experience in developing high-performance scientific instruments and analytical solutions. It offers an

HORIBA Scientific has 200 years of experience in developing high-performance scientific instruments and analytical solutions. It offers an