Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

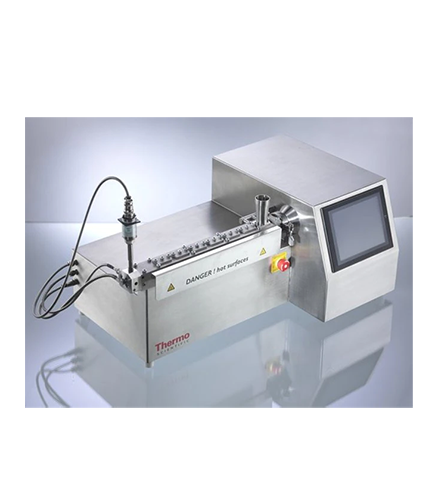

Thermo Scientific Process 11 Parallel Twin-Screw Extruder

- Minimized sample material usage (20 g)

- Throughput range 20g/h to 2.5kg/h

- Small footprint bench top design that is easily transportable

- Segmented screw design with removable top half barrel

- Easy-to-operate touch screen with integrated feeder control

- Geometrically scalable screw and barrel design across portfolio

Introducing the Thermo Scientific Process 11 Parallel Twin-Screw Extruder

The Process 11 Parallel Twin-Screw Extruder was created with a user-friendly touch-screen operation that features an integrated feeder control and easily removable product contact parts. The compact monocoque design minimizes the usage of lab space and is ideal for fume hood applications. The screw elements and barrel design scale geometrically across all Thermo Scientific extruders and allow easy process scale-up.

Key Features

he Process 11 Parallel Twin-Screw Extruder Features:

- Minimized sample material usage (20 g)

- Throughput range 20g/h to 2.5kg/h

- Small footprint bench top design that is easily transportable

- Segmented screw design with removable top half barrel

- Easy-to-operate touch screen with integrated feeder control

- Geometrically scalable screw and barrel design across portfolio

Key Benefits

Recommended for:

Materials:

- Polymers

- Additives

- Adhesives

- Food

- Cosmetics

Applications:

- Compounding

- Masterbatches

- Nanocomposites

A small footprint reduces lab space requirements and lower ingredient consumption reduces environmental contamination and operator exposure.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

| Amperage | 16A |

| Barrel Length L/D | 40 L/D |

| Max. Screw Speed | 1,000 rpm |

| Voltage | 230 V |

| Barrel Bore Diameter | 11mm |

| Barrel Zones | 7 x 5 L/D electrical heated (optional water cooled) |

| Description | Process 11 – Parallel Twin-Screw Extruder |

| Height (Metric) | 41cm |

| Length (Metric) | 82 cm |

| Max. Temperature | 350°C (450°C as option) |

| Screw Diameter | 11mm |

| Screws | Fully segmented, co-rotating |

| Torque per Shaft | 6 Nm |

| Typical Output | 20 g/H up to 2.5 kg/h (depending on material) |

| Width (Metric) | 48 cm |

| Unit Size | Each |

| Catalog number | Unit Size | Barrel | Description | Screws | Price (CAD) | |

|---|---|---|---|---|---|---|

| 567-7600 | Each | 7 x 5 L/D electrical heated (optional water cooled) | Process 11 – Parallel Twin-Screw Extruder | Fully segmented, co-rotating |