Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

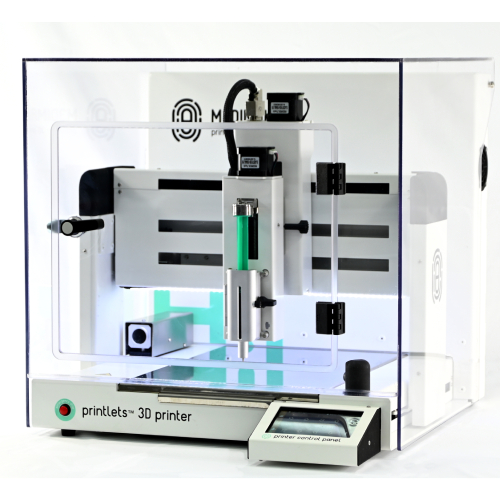

Nanoparticle Deposition System – NL50 – Nikalyte

- Nikalyte NL50 benchtop system enables the deposition of ultra-pure metallic nanoparticles in research laboratories.

- It’s designed to be user-friendly and convenient, allowing for easy and repeatable deposition of non-agglomerated nanoparticles on samples up to 50mm in diameter.

- The deposition process is operated through a touchscreen interface, making it simple to use. Training for routine operations can be completed in as little as 10 minutes.

- NL50 allows for the modification of process variables, including nanoparticle size, distribution, and layer thickness.

- Samples can be loaded through a clear chamber door and can undergo plasma cleaning before deposition.

- Changing the source materials can be done quickly, within 5 minutes.

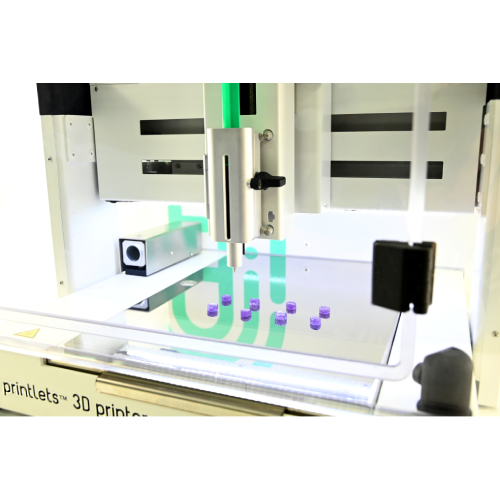

- The vacuum deposition process ensures the production of ultra-pure nanoparticles without hydrocarbons or other contaminants commonly found in chemical techniques.

- The nanoparticle coating is directly deposited onto the substrate, and after a typical cycle time of 30 minutes, it is ready for analysis without the need for additional drying or purification steps.

Introducing the Nanoparticle Deposition System – NL50 – Nikalyte

The Nikalyte NL50 – Nanoparticle Deposition System brings the possibility of depositing ultra-pure metallic nanoparticles to every research laboratory. Specifically designed to be easy and convenient to use, the NL50 is capable of routinely and repeatably depositing non-agglomerated nanoparticles onto samples of up to 50mm diameter.

Touchscreen operation makes the deposition process as simple as possible. Training for routine operations can take as little as 10 minutes. It also allows process variables to be modified to adjust parameters such as nanoparticle size, distribution and layer thickness.

Samples are loaded through the clear chamber door and can be plasma cleaned in the chamber before deposition. The source materials can be easily changed in under 5 minutes.

The vacuum deposition process produces ultra-pure nanoparticles that are free of hydrocarbons or other contamination, which typically plague chemical techniques. The nanoparticle coating is deposited straight onto your substrate and after a typical cycle time of 30 minutes is ready for analysis; no further drying or purification steps are needed.

Key Features

- Touch Screen: allows fully automated recipe control and supports preloaded settings for common materials

Key Benefits

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

NL50 Weight: approx. 60Kg (113lbs)

NL50 Dimensions: (LXWXH) 70x50x60cm (27.6×19.7×23.6inches)

|

Consumables |

|

| Target size | 1 inch (25.4mm) diameter, max 3mm thick |

| Max Sample Size | 50 mm diameter |

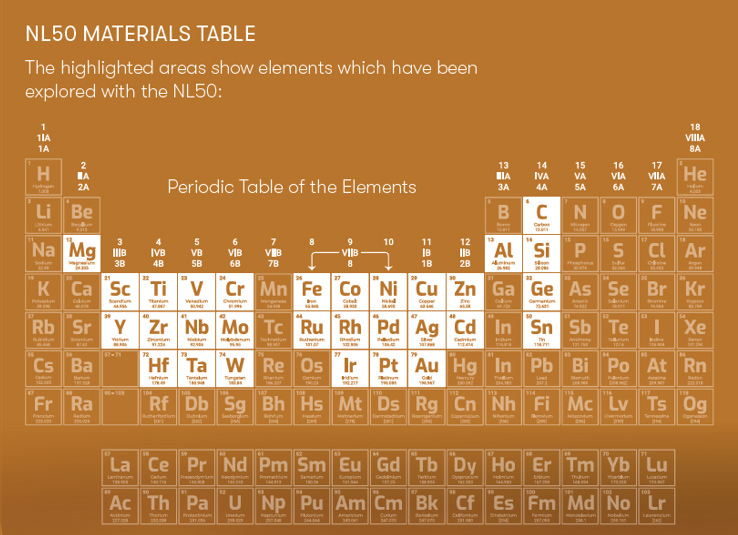

| Materials | Conducting materials, including

Ag, Au, Pt, Cu, Ni, Ti, Ir |

|

Utilities |

|

| Power | Single phase IEC, AC @110-260 v, 50-60 hZ |

| Gas | Argon (process gas)

Nitrogen (vent gas) High-pressure air (pneumatics) 6mm compression fittings |

| Water | 1 L/min (0.3 US GPM)

2×10 mm compression fittings |

| Pumping | DN25KF, 120 L/m(7.2m3/h) backing pump required (provided as an optional extra) |

View similar instruments from Nikalyte.