Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Ultra High Vacuum- Alloy Nanoparticle Deposition

- NL-UHV enables the generation and deposition of nanoparticles in an Ultra-High vacuum to create functionalized surfaces on samples.

- The properties of the nanoparticle coatings can be precisely controlled, including size, composition, and structure, allowing for tailored properties.

- NL-UHV instruments allow the direct deposition of ultra-pure nanoparticles on a wide range of substrates and materials.

- The film density can be adjusted, and the coating adheres well to the sample surface.

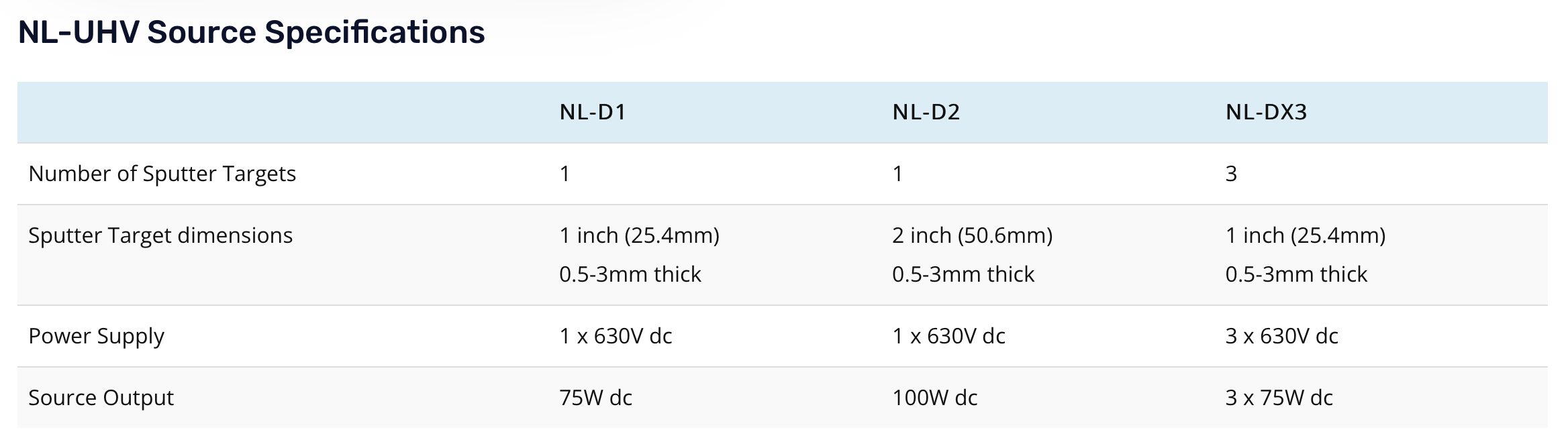

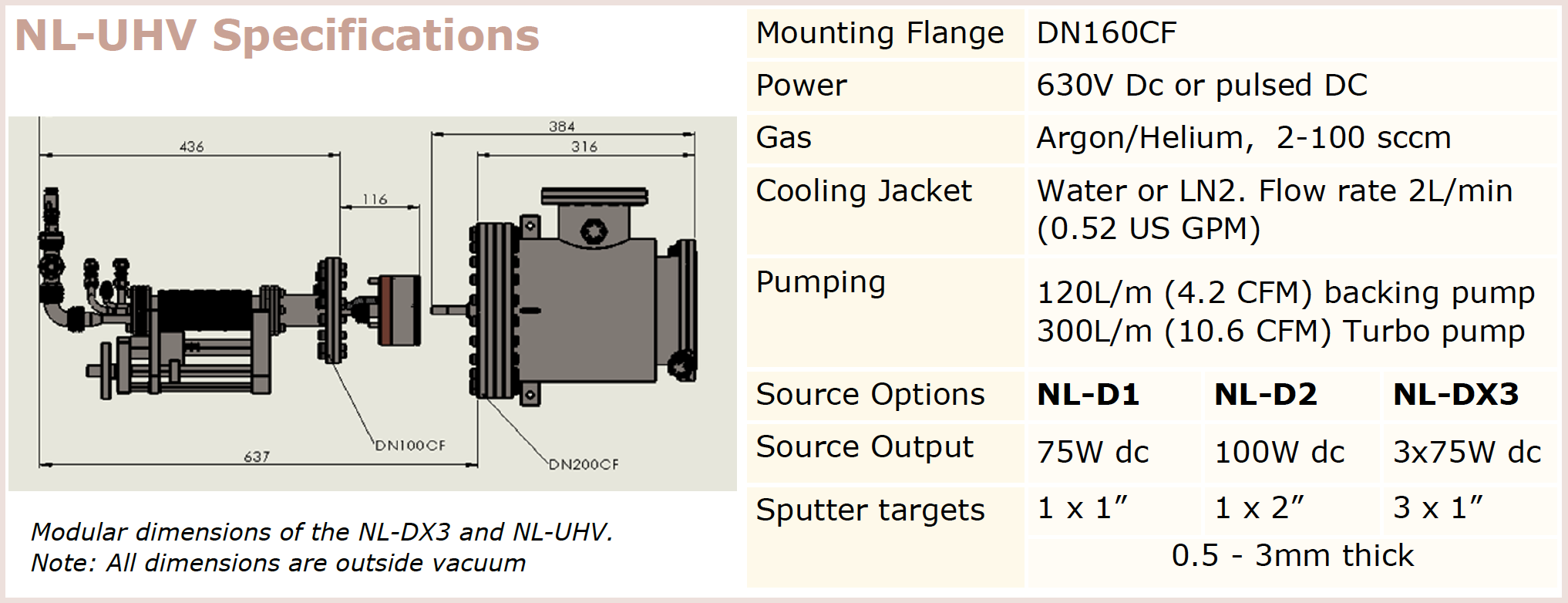

- Available in different configurations, including single 1″ and 2″ sources, as well as the triple 1″ source NL-DX3, which enables the deposition of up to three materials individually or as alloys.

- The NL-QMS mass filter offers advanced control over nanoparticle deposition, allowing the scanning or filtering of nanoparticles by mass or diameter in real-time.

- The NL-QMS is operated through user-friendly WindowsTM software, providing intuitive control over the deposition process.

Introducing the Ultra High Vacuum- Alloy Nanoparticle Deposition

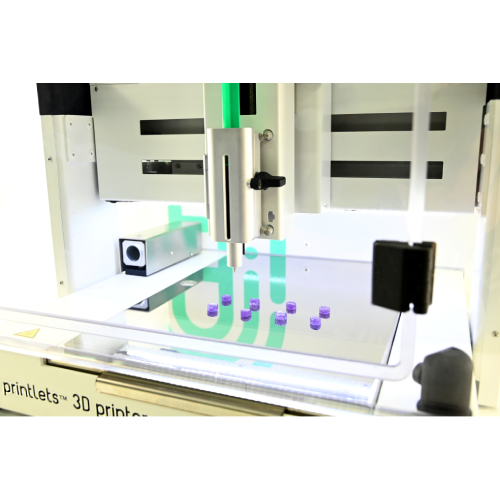

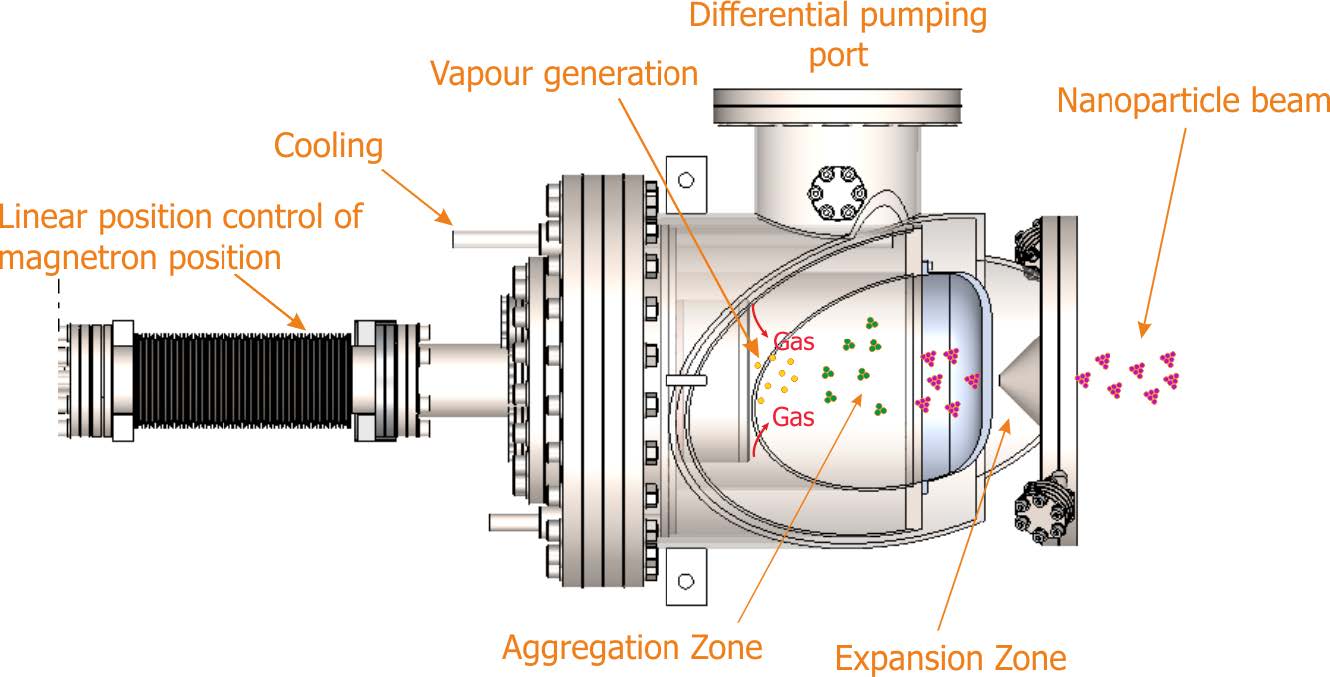

The Nikalyte NL-UHV, Alloy Nanoparticle Deposition instrument, range enables the generation and deposition of nanoparticles in Ultra-High vacuum onto your sample to create a functionalised surface. The properties of the nanoparticle coatings can be tailored through the precise control over the size, composition and structure of the nanoparticles.

Unlike chemical techniques, the NL-UHV range of instruments allows the direct deposition of ultra-pure nanoparticles onto various substrates and materials. The film density can be tuned and the film itself can be highly adherent to the sample surface.

The NL-UHV is available with a single 1”, 2” source or a triple 1” source, the NL-DX3. The NL-DX3 allows the deposition of up to three materials individually or as alloys using two or three materials simultaneously.

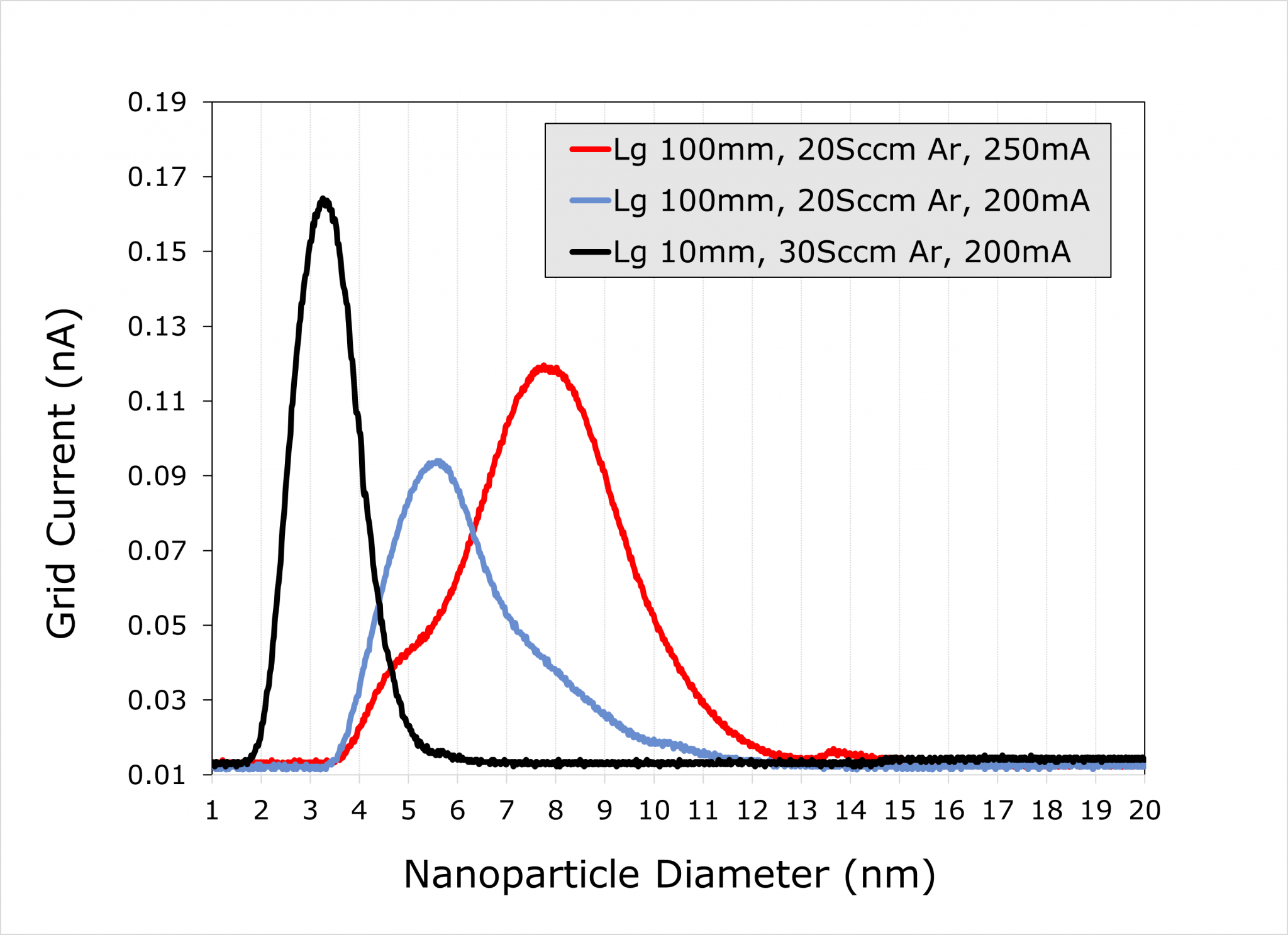

For the ultimate control of nanoparticle deposition, the Nikalyte NL-QMS mass filter allows the deposited nanoparticles to be scanned or filtered by mass or nanoparticle diameter in real time, allowing you to optimise the growth conditions. The NL-QMS is controlled via our simple and intuitive WindowsTM software.

Key Features

Key Benefits

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.