Dalia G. Yablon and Andy H. Tsou, ExxonMobil Research and Engineering, Clinton, NJ

|

A commercial impact copolymer (ICP), amulticomponent material typically used inautomotive and appliance applications where a balance of stiffness and toughness is needed, was studied with the NanoRack™ Sample Stretching Stage accessory on the MFP-3D™Atomic Force Microscope to investigate material deformation and interface adhesion as a function of tensile stress. Effects of deformation were observed within both the polypropylene and ethylene-propylene components, as well as at the interface between the two materials. There are no other direct measurement methods available to determine interfacial adhesive strength of polymer blends, and so AFM investigations of micro-domain deformation such as the one described here could be used ultimately to provide a direct determination of interfacial adhesion in complex polymer containing materials such as ICP. Studies of this kind improve our understanding of material structure-propertyrelationships, ultimately enabling manufacture of better quality products. Application to Impact Copolymer (ICP)The commercial impact copolymer used for this study is composed of a polypropylene (PP) matrix with micron-sized domains of ethylene-propylene (EP) rubber domains produced in a serial polymerization reactor. Dogbone-shaped samples were molded of the impact copolymer measuring at ~20mm (middle straight part of dogbone) by ~4mm in width by 0.2mm thickness. A portion of the straight part of the dogbone was cryo-faced at -120°C with a cryomicrotome to ensure a smooth sample and to remove the thin polymer |

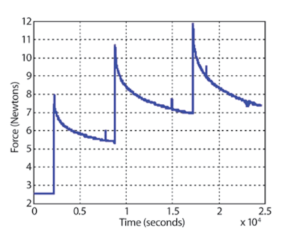

Figure 1: Stress (Newtons) vs. time (seconds) curve of ICP as it is being stretched on the NanoRack. surface layer that forms during the compression molding process (also referred to as a ‘polymer skin’), leaving a small and smooth surface area in the middle of the dogbone that was suitable for imaging. The sample was mounted into a NanoRack Sample Stretching Stage with smooth grips. The NanoRack is a high-strain, high-travel manual stretching stage that provides two-axis stress control of tensile loaded samples and also allows control of the sample image region under different loads. Automatic load cell calibration provides integrated force measurements with MFP-3D images or other measurements and returns both stress and strain data. Figure 1 shows real-time stress vs. time curves of the ICP as the sample is being pulled in the NanoRack. The baseline force is |