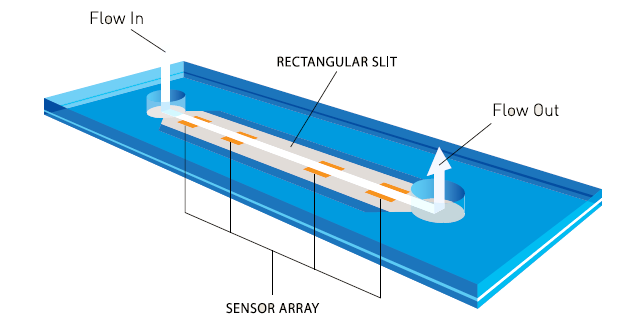

Viscometer-Rheometer-on-a-Chip (VROC®) combines microfluidic and MEMS (Micro-Electro-Mechanical Systems) technologies.

The Superior Viscometer

Compared to conventional viscometers and rheometers, microfluidic devices offer several advantages. They:

- Require small sample volumes of liquid

- Impose high shear rates without encountering flow stability

- Maintain complete enclosure of fluid to prevent evaporation

- Can be used as simple flow-through device

More Accurate Viscosity Measurements

Products built on our technology platform completely characterize flow, helping you achieve cost-effective flow and material characterization. Complete viscosity characterization is essential in the production of complex liquids with non-Newtonian viscosity characteristics.

Our technology quantifies true flow properties, whereas many existing products only qualitatively approximate apparent properties.

Why MEMS and Microfluidics for Viscosity?

Microfluidics deals with the behavior, precise control, and manipulation of small (microliter and nanoliter) volumes of liquids. Microfluidics enables high throughput analysis.

MEMS chips integrate mechanical elements, sensors, actuators, and electronics on a common silicon substrate, using microfabrication technology.

Through its hybrid microfluidics/MEMS technology, RheoSense has developed smaller, smarter, and faster micro-scale-sample viscometers, which can measure fluids’ viscosity in all types of environments.

Principle of RheoSense Viscometers

VROC® sensors read viscosity by measuring the pressure drop as a test liquid flows through its flow channel. This is a well-known application of rheometry principles (K. Walters, Rheometry, Chapman and Hall, London, 1975) and also listed in US Pharmacopeia.

As the test liquid is forced to flow through the sensor’s flow channel, the rheometer measures pressure at positions increasingly far from the inlet.

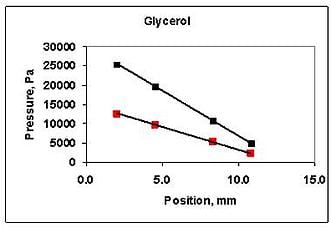

In this resulting (example) plot of measured pressure versus sensor position, the slope of the straight line is proportional to the viscosity.

Our Viscometer Implementation

To create a dynamic micro-sample viscometer, RheoSense took this principle and added microfludics, while reducing the device’s size. Our resulting VROC® technology offers capabilities well beyond the limits of conventional viscometers.

VROC® is capable of making measurements not possible with other instruments…the ability of the RheoSense viscometer to measure very small sample quantities is also useful. We have found the instrument to be accurate and reliable

— A corporate R&D Customer