Description

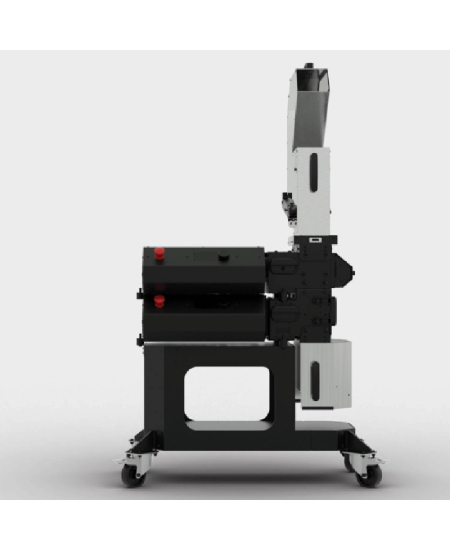

The Filament Maker ONE is a desktop extrusion system designed to give labs, classrooms, and researchers complete control over filament development. Compact yet powerful, it lets you make your own 3D printing filament with precision and reliability.

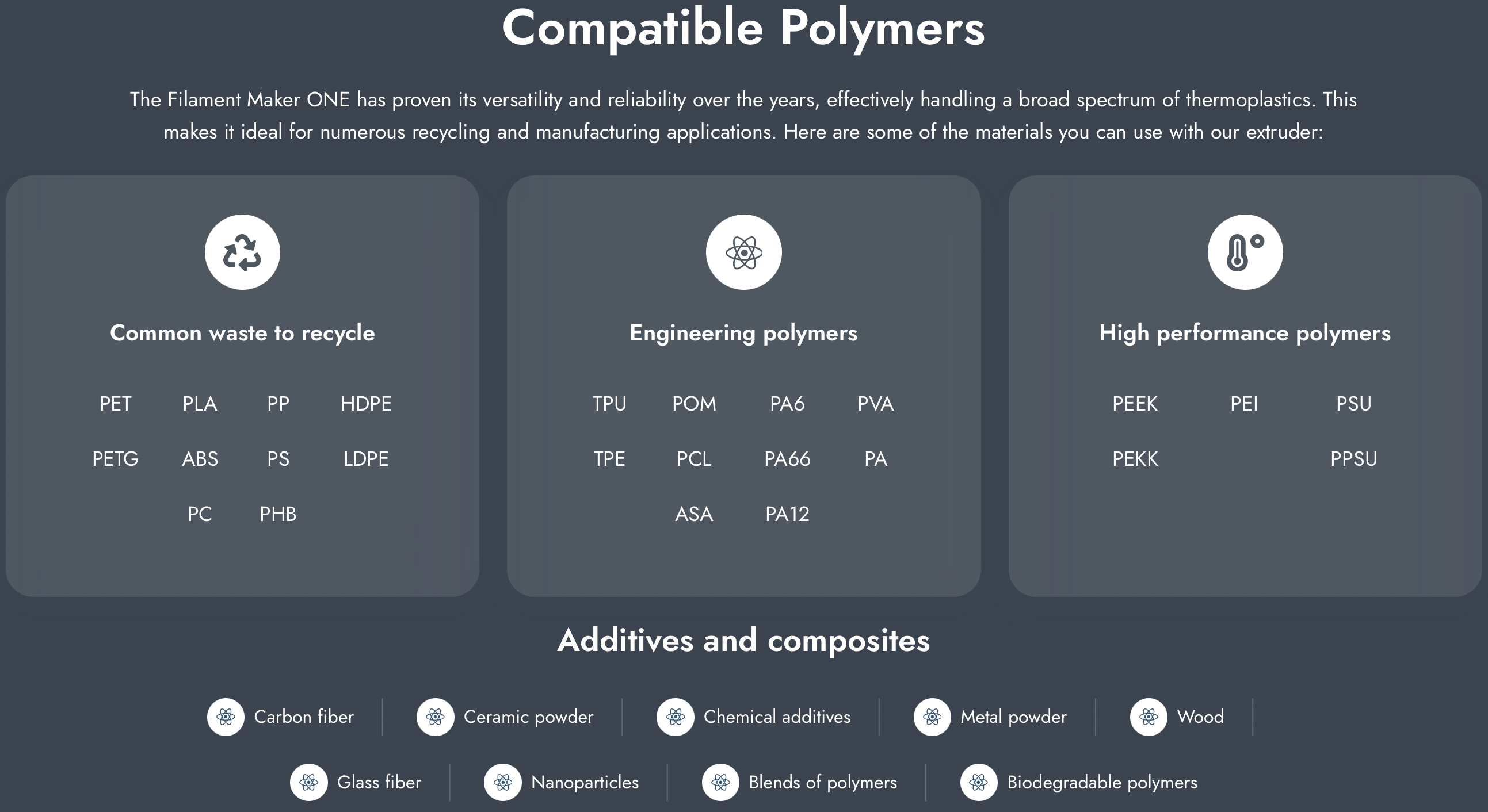

Key Features:

- Produces filament between 0.5 mm and 3.0 mm with a tolerance of ±0.05 mm

- Handles common and advanced plastics (PLA, ABS, PETG, PC, PEEK, and more)

- 4 heating zones (up to 450 °C in HT version) for stable extrusion

- Real-time monitoring & data export of screw RPM, puller speed, filament diameter, and motor current

- OLED display interface with preset material profiles and custom options

- Extruder screw options:

• Composer Screw – for blending additives and composites

• Precision Screw – for consistent, high-throughput extrusion - Vertical filament path for roundness and better spooling

- Optical sensor (43 μm precision) for accurate diameter control

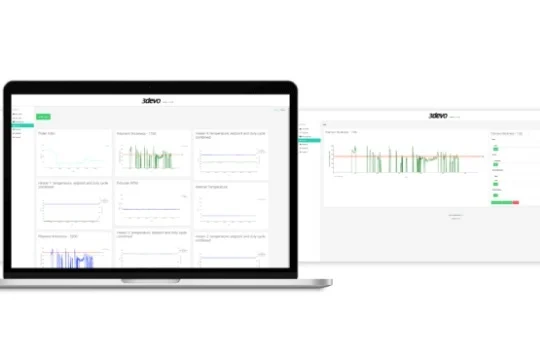

- Dual fan cooling system and adjustable spool holder (up to 240 mm × 120 mm spools)

- Compact footprint: 506 × 216 × 448 mm; weight 24.5–27 kg

Specifications at a Glance:

- Power use: 300–400 W (average), 1,300 W (max)

- Voltage: 110–230 V, 50/60 Hz

- Robust, nitrided steel extruder screw for durability and additive mixing

The Original Filament Maker:

The Filament Maker ONE is our original desktop extrusion system, trusted by professionals since 2016 for hands-on filament development and material testing.

Built for consistent performance across a wide range of polymers, it’s the ideal tool for teams starting or scaling their R&D workflows with confidence.

Two Available Screws:

- Composer Screw: Designed with an extended mixing zone to ensure thorough blending of additives, fillers, fibers, or colorants. The go-to choice for developing complex compounds or testing functional material formulations.

- Precision Screw: Built for high-throughput extrusion of standard or recycled polymers. Ideal for fast, stable filament production when processing pure materials or simple blends.

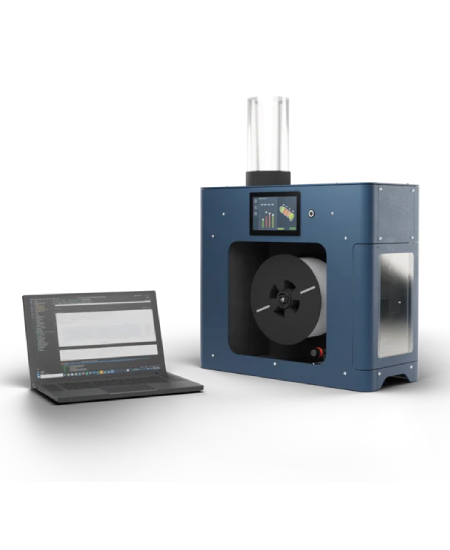

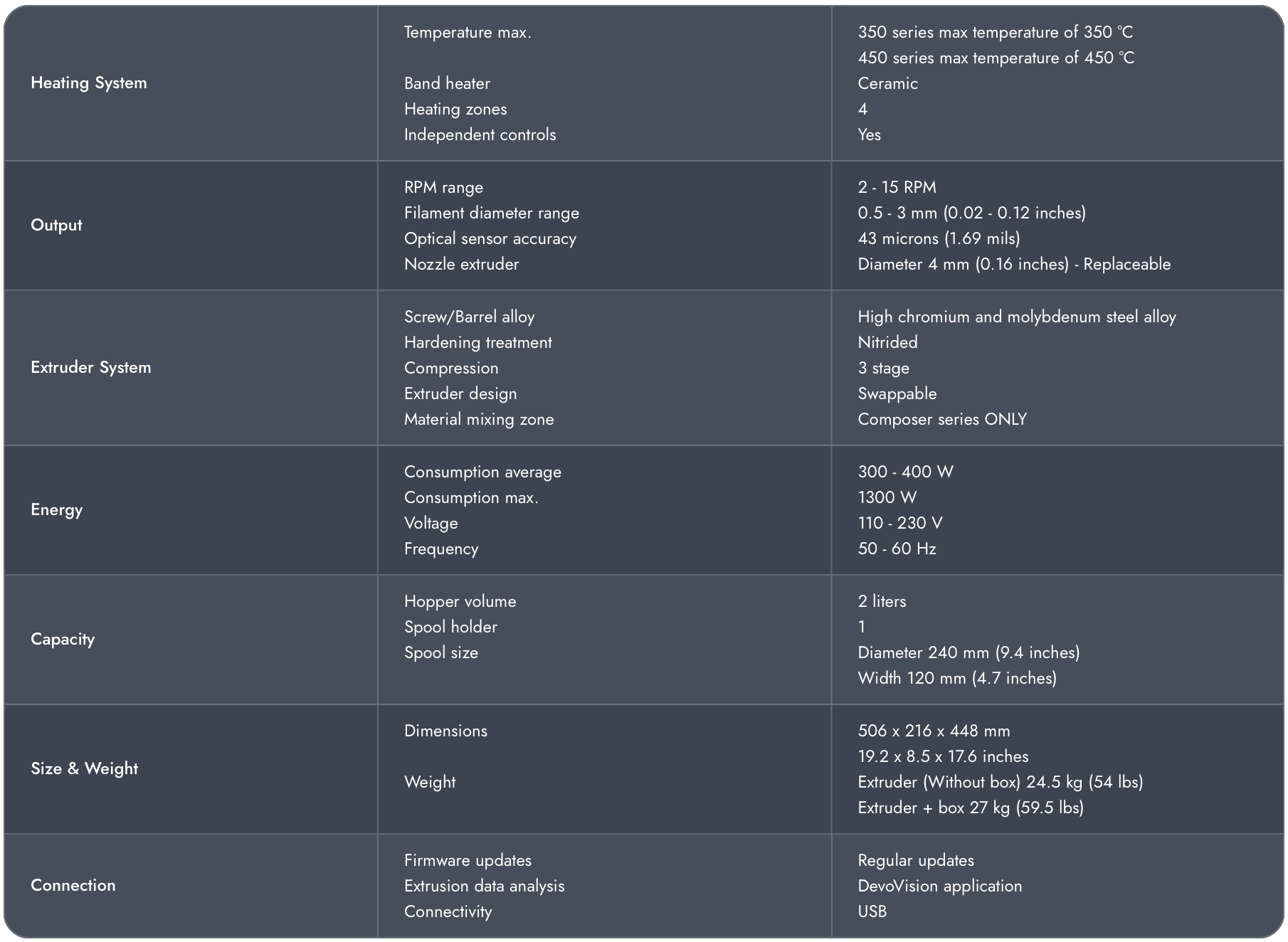

Comprehensive Data Monitoring:

Live Process Insights: Monitor key metrics like heater settings, filament thickness, and motor current in real time to maintain precise system control.

- Detailed Analytics: Track puller speed and screw RPM, all visualized in graphs, and easily export the data to Excel for further analysis.

- Optimize Performance: Leverage this comprehensive data to fine-tune your material settings, ensuring consistent, high-quality filament production.

Intuitive Control Panel:

Streamlined Interface: Navigate with ease through an OLED display and a simple rotate-and-push button.

- Quick-Set Profiles: Jumpstart your projects with standard material presets (PLA, ABS, PA12, PC, PEEK, and PS) or tailor custom profiles for unparalleled results.

Precision and Quality:

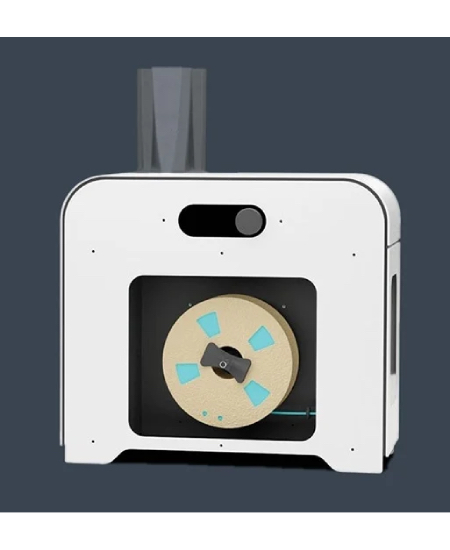

Vertical Extrusion: Guarantees precise filament roundness and direct spooling, enhancing the quality of your 3D prints.

- Cutting-Edge Cooling and Spooling: Enhanced by a balanced dual fan system for even cooling and a precision spooling setup with an adjustable positioner and automatic spooling function

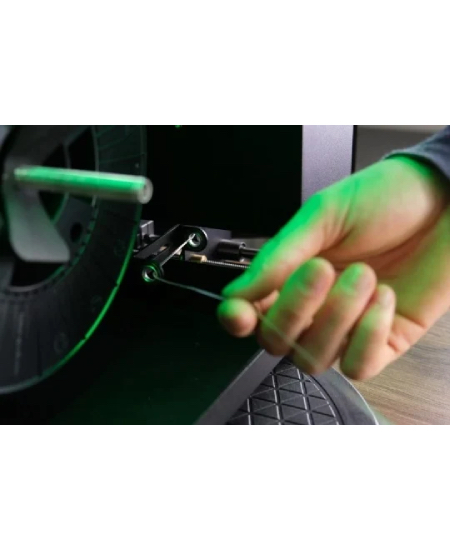

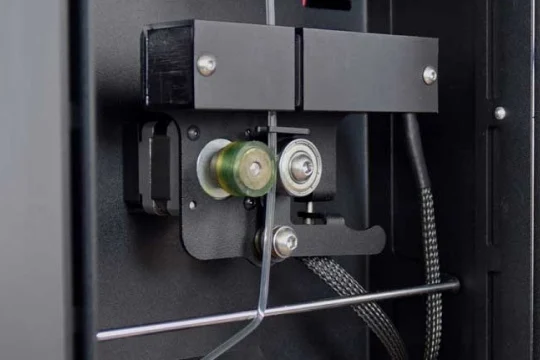

Optical Sensor and Puller:

Unparalleled Accuracy: The optical sensor measures filament diameter with 43-micron precision.

- Adaptive Puller System: Adjusts speed for consistent diameter control, with interchangeable wheels for various temperatures.

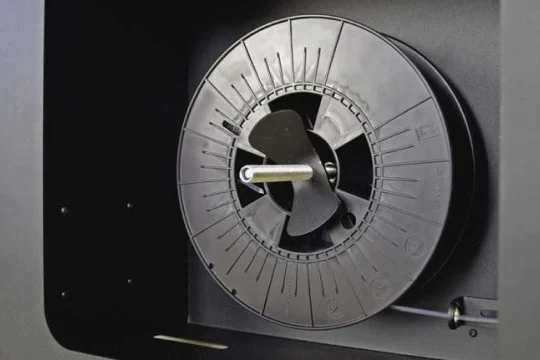

Automatic Spooling Mechanism:

Adaptable Spool Mount: Supports various spool sizes for flexibility in filament production.

- Customizable Spooling: Set specific dimensions for perfectly wound spools, while the built-in slipper clutch adjusts tension for smooth operation.

- Precision Spooling: Ensures tidy, tangle-free spools, supporting up to 240mm diameter and 120mm width.

The Filament Maker ONE extrusion system is perfect for labs and schools experimenting with materials, recycling plastics, or producing small batches of filament with professional consistency.

Click here to view similar products from 3devo.