Description

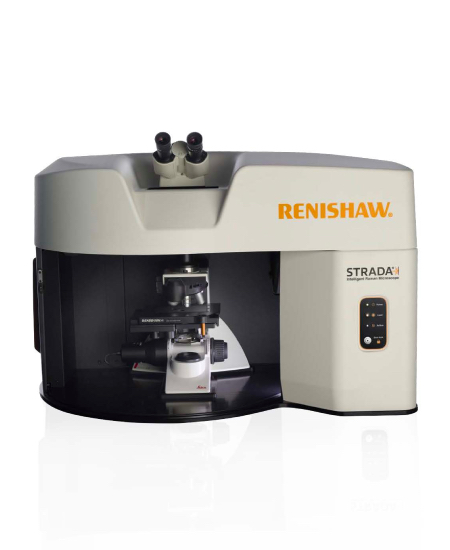

Meet the DW14 Desiccant Dryer — a smart dehumidifying dryer made especially for drying plastics before they’re turned into filament.

Why it matters:

Moisture in plastic ruins filament quality—causing bubbles, weakening, or bad prints. The DW14 helps prevent that by drying the plastic well before extrusion.

How DW14 Desiccant Dryer works:

- Inside is a honeycomb wheel coated with molecular sieve material. That wheel spins, passing moist air through drying and regeneration zones.

- There are three main parts:

1. Drying section: pulls moisture out of the air going toward plastic hopper

2. Regeneration section: reheats a part of the wheel to remove absorbed moisture

3. Cooling section: cools it again so it’s ready to dry more air

Features of DW14 Desiccant Dryer you’ll love:

- Programmable timer: you can schedule drying to start before production.

- Material presets: built-in settings for common plastics like PLA, ABS, PETG. You can also save your own recipes.

- Protection safeguards: it watches the return air temp and load, so it won’t over-dry or damage plastics.

- Energy-efficient: It can save up to 40% energy compared to older twin-tower dryers.

- No external lines needed: Works without compressed air or cooling water hookups.

- Modular design: The dryer is easy to maintain. Tool-free access lets you clean or swap parts.

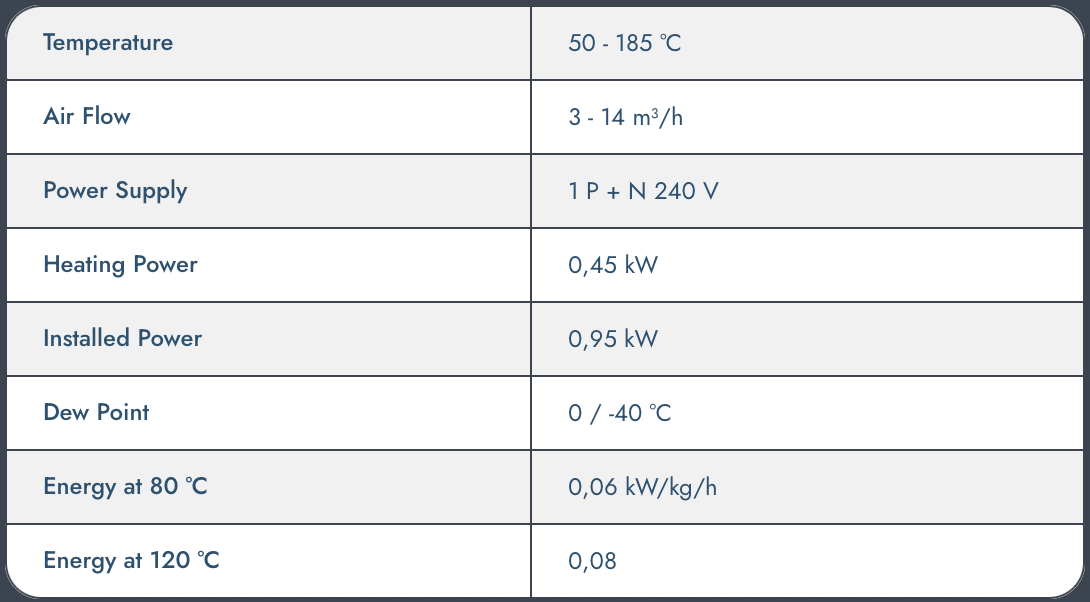

Performance & specs:

- Drying temperature: 50–185 °C

- Airflow: 3 – 14 m³/h

- Dew point control to –40 °C

- Hopper options: 6 L or 15 L

- Power: ~0.95 kW installed, heating ~0.45 kW

With the DW14 dehumidifying dryer, your plastic stays dry, your filament stays high quality, and your extrusion goes smoother.

Click here to view similar products from 3devo.