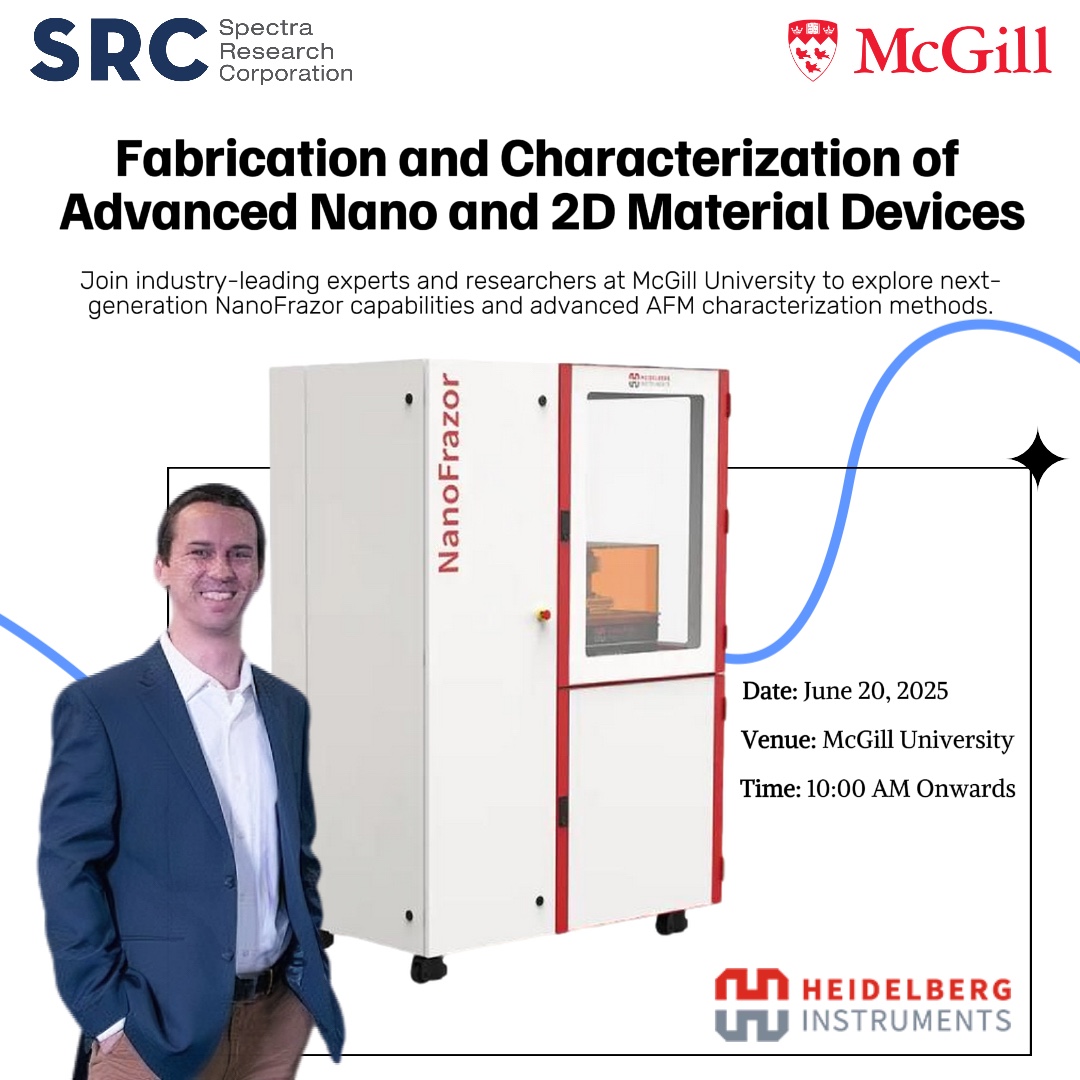

Fabrication and Characterization of Advanced Nano and 2D ...

Date: June 20, 2025 Time: 10:00 AM Onwards Venue: McGill University – Room 103, Rutherford Physics Building Address: 3600 University Street, Montreal, Quebec, Canada H3A 2T8 Event Overview: Spectra Research Corporation (SRC) in collaboration with Heidelberg Instruments invites you to an exclusive...

Times: Option 1: 10 am CEST (More suitable for Europe and Asia) Option 2: 6 pm CEST (More suitable for North and South America) W...

SRC at the Canadian Chemistry Conference and Exhibition (CSC 2025) Date: June 15–17, 2025Location: Ottawa, Canada Booth #: 517 Discover C...

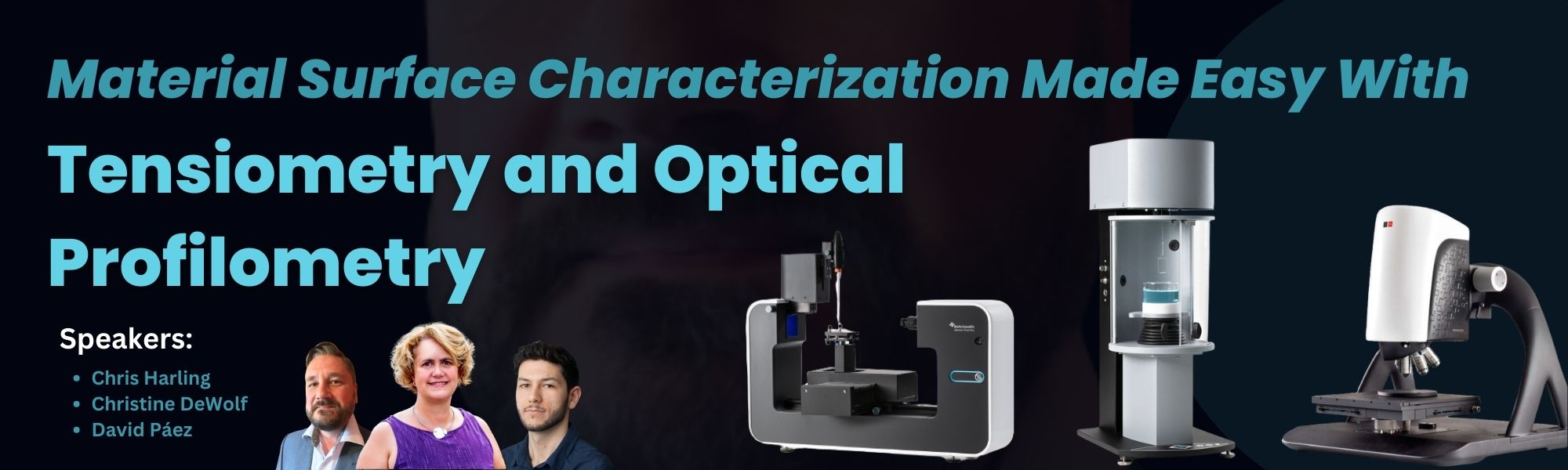

In today’s fast-paced industries, understanding surface texture is key to improving product quality and manufacturing efficiency. This we...

Date and Time: 📅 October 22nd, 2024 🕘 Session 1: 09:00 AM – 10:00 AM CET 🕓 Session 2: 04:00 PM – 05:00 PM CET Overview: Wetta...

Join us for an insightful webinar where we delve into the revolutionary world of nanoparticle coatings and the game-changing Nikalyte NL5...

In this webinar, you’ll push the limits of SensoPRO. Image analysis so fast you won’t believe it. Data and parameters you never thought y...

Join us for an enlightening day of cutting-edge insights into Material Characterization and Surface Science, hosted in collaboration with...

Join us for an enlightening day of cutting-edge insights into Material Characterization and Surface Science, hosted in collaboration with...

We’d love to see you at Sensofar Event 22! We believe that the future is built by listening to the needs of our users, as well as the mar...

September 28 @ 12:00 pm – 1:00 pm Join CCAT and Sensofar for a free webinar about high magnification inspection of critical dimensi...

Presented by Ben Schmidt, Ph.D., Senior Staff Scientist July 14, 2022 at 10:00 a.m. CST Register HERE X-ray photoelectron spectros...