Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

3devo

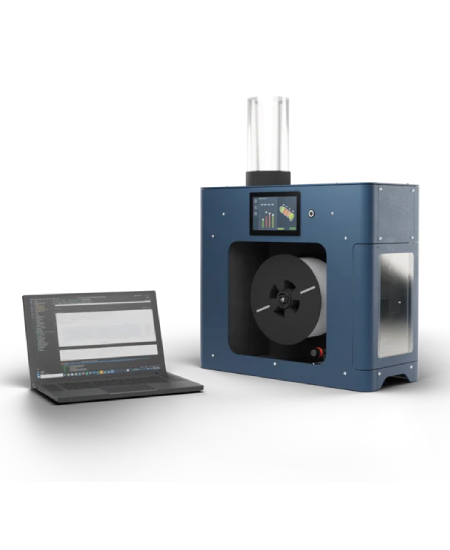

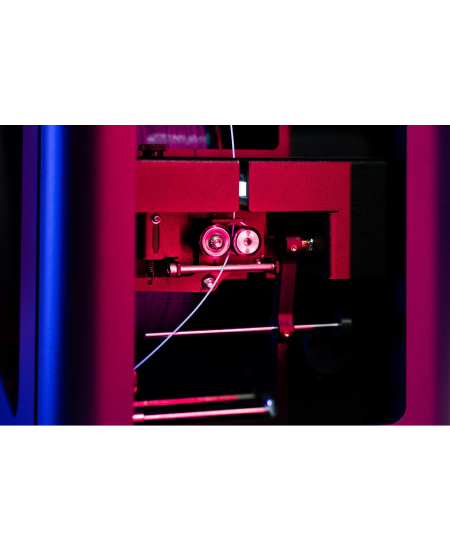

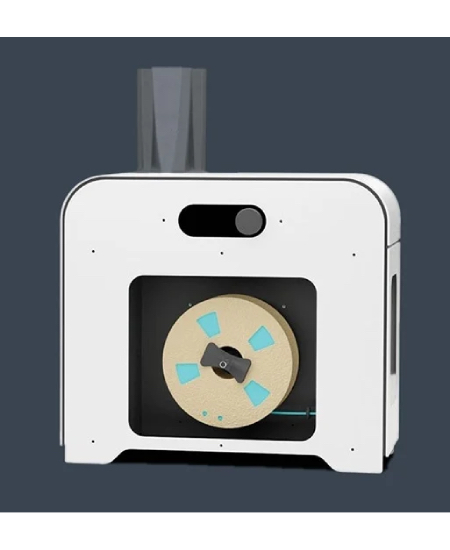

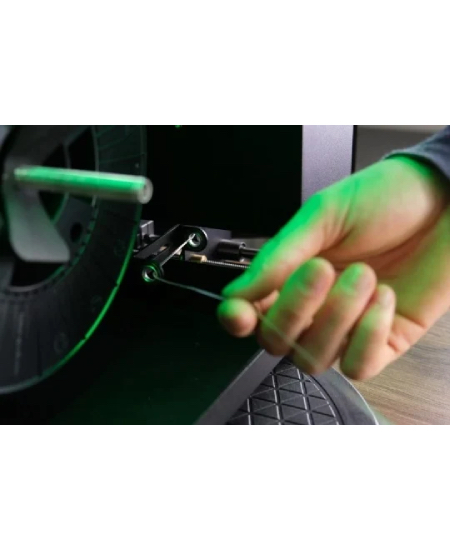

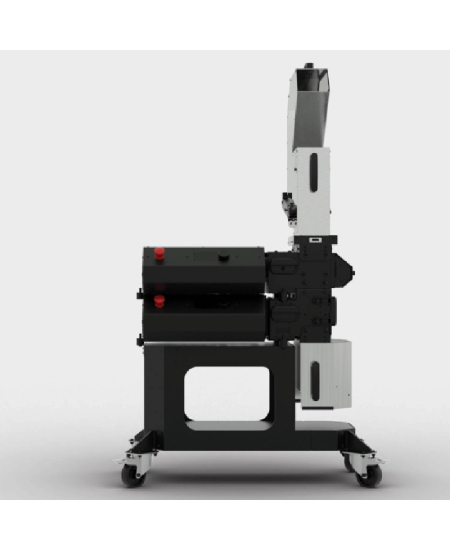

3devo is a Dutch technology company that develops advanced equipment for plastic recycling and filament production. The machines allow users to turn plastic waste or raw materials into high-quality 3D printing filament, giving businesses, researchers, and educators more control over their material use. With products like the Filament Maker and the GP20 Plastic Shredder, 3devo makes it possible to experiment with new materials, reduce waste, and create a more sustainable workflow for 3D printing and manufacturing.