Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

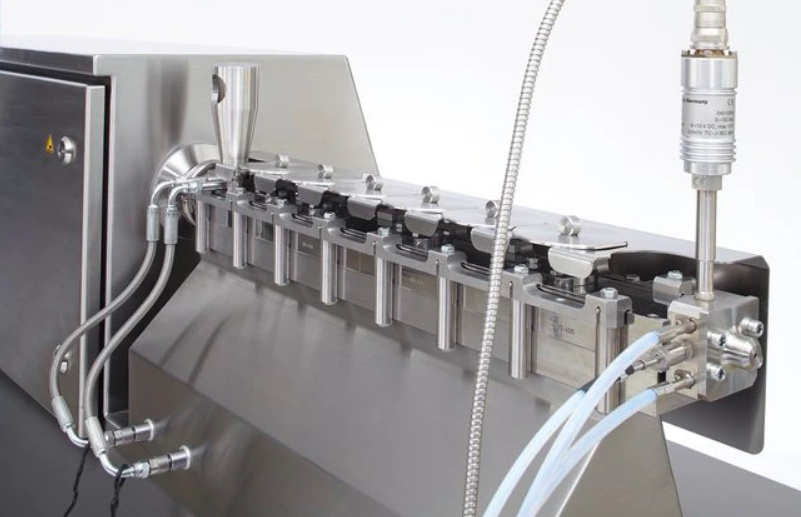

Thermo Scientific Pharma 16 Twin-Screw Extruder

- 2-in-1 process design – quickly disassemble parts for easy cleaning and process switching from HME to TSG.

- Simple continuous process integration – plug-and-play functionality with upstream and downstream process equipment (e.g., feeders, chill rolls, pelletizers, dryers, etc) simplifies production line design.

- Less optimization time, cost and effort – extruder process parameters are scaleable to larger Thermo Scientific extruders due to geometric similarity with minimal use of expensive ingredients.

Introducing the Thermo Scientific Pharma 16 Twin-Screw Extruder

The Pharma 16 Twin-Screw Extruder is ideal for pilot-scale, continuous HME or TSG processes used for research, development or production in the pharmaceutical industry. Companies can bring products to market faster and with high quality by developing a continuous process for solid dosage forms compared to a batch process. Effects of pilot-scale process conditions on drug formulations for drug delivery and pharmaceutics can easily be studied using the Pharma 16 Twin-Screw Extruder.

Key Features

Pharma 16 Twin-Screw Extruder highlights:

- 2-in-1 process design – quickly disassemble parts for easy cleaning and process switching from HME to TSG.

- Simple continuous process integration – plug-and-play functionality with upstream and downstream process equipment (e.g., feeders, chill rolls, pelletizers, dryers, etc) simplifies production line design.

- Less optimization time, cost and effort – extruder process parameters are scaleable to larger Thermo Scientific extruders due to geometric similarity with minimal use of expensive ingredients.

Key Benefits

Rapidly develop pharmaceutical formulations and adopt continuous processing methods using the Thermo Scientific™ Pharma 16 Twin-Screw Extruder. The Pharma 16 Twin-Screw Extruder can switch between continuous hot melt extrusion (HME) or wet granulation (TSG) with ease. Optimize drug process development parameters with less time and effort than batch processes and easily scale-up to larger Thermo Scientific™ extruders with using minimal amounts of expensive APIs and excipients.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

| Catalog number | Unit Size | Description | Price (CAD) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 553-1040 | – | Pharma 16 Twin-Screw Extruder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||